Successful supplier onboarding is crucial for companies that want to make their supply chain management processes efficient and sustainable. The process ensures that new suppliers meet the quality, compliance and business requirements. At the same time, it forms the basis for smooth cooperation and a sustainable supplier relationship. Modern, digital workflows and integrated software solutions such as SC-Manager make onboarding faster, more transparent and more secure.

1. what is supplier onboarding?

Supplier onboarding describes the structured integration of new suppliers into a company’s supply chain. It involves much more than the initial contact via a form on the website. Rather, it is a multi-stage overall process – from self-registration and self-disclosure to qualification, inclusion in the vendor base and an active business relationship. The aim is to systematically integrate suppliers, minimize risks and ensure efficient collaboration right from the start.

1.1. Definition of supplier onboarding

Structured onboarding covers all steps from registration to ERP integration. It standardizes the creation and qualification of new business partners and ensures that all relevant information is checked and documented. This minimizes risks such as missing evidence or incomplete data. Terms such as supplier enablement or supplier qualification also describe similar approaches to digital supplier integration.

1.2. Onboarding form as a starting point

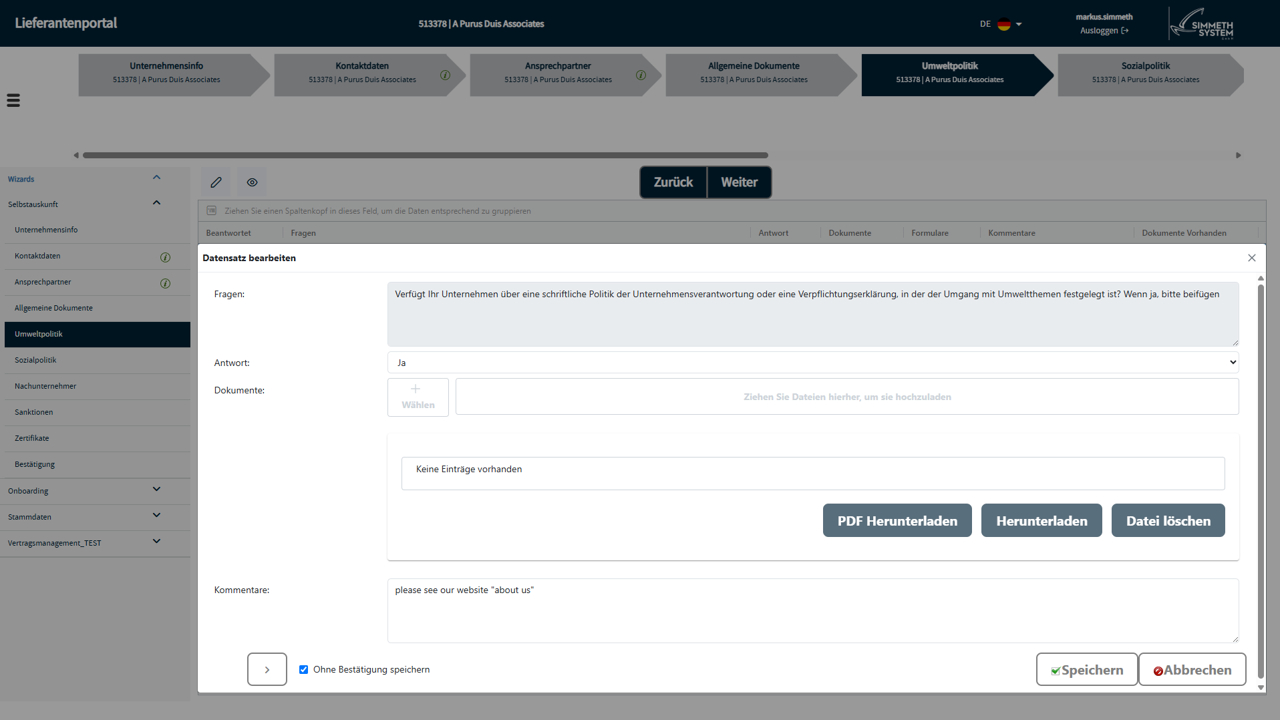

The onboarding form serves as the starting point for data collection. Potential suppliers register via the company website and provide their information there. This data is automatically transferred to the supplier management system and triggers the review and approval process. The documents and information required may vary depending on the industry and product group. A clear qualification concept ensures that the requirements are transparent and comparable.

Category

Company data

Contact persons

Financial information

Certificates & evidence

Compliance information

Typical data

Name, address, legal form

Contact details, responsible person

Bank details, VAT ID no.

ISO 9001, environmental certificates

Sustainability declarations, Supply Chain Act

The onboarding form serves as the starting point for data collection. Potential suppliers register via the company website and provide their information there. This data is automatically transferred to the supplier management system and triggers the review and approval process. The documents and information required may vary depending on the industry and product group. A clear qualification concept ensures that the requirements are transparent and comparable.

2. the supplier onboarding process

The onboarding process is multi-stage and is ideally supported completely digitally. Modern systems such as SC-Manager combine self-registration, supplier self-assessment and qualification into an end-to-end workflow.

2.1. Workflow-supported testing

Optimal onboarding is based on workflow-controlled processes. These workflows control the checks, distribute tasks to the responsible departments and use traffic light systems to ensure that all open issues are immediately visible. Automated reminders prevent delays, while role-based approvals guarantee traceability and audit compliance. Close integration with areas such as Risk & Compliance and Collaboration plays a key role here. This integration creates a consistent audit trail and supports companies in complying with the Supply Chain Act.

2.2. Step-by-step process

The onboarding process is divided into several phases:

- Registration: Suppliers enter their master data via a form or portal.

- Self-disclosure and document verification: Companies request specific information such as questionnaires, certificates or evidence. These are submitted and checked digitally.

- Automated qualification: algorithms and workflows are used to assess the suitability of the supplier. Traffic light systems indicate progress.

- Approval and ERP integration: After a successful check, the supplier is automatically transferred to the vendor master data. The supplier becomes an official business partner, ensuring the quality of suppliers and their products

2.3. Clear responsibilities

Structured onboarding only works with clear roles. Purchasing initiates the process and checks master data, the compliance department monitors regulatory requirements and master data management enters the checked information into the system. All parties involved are always informed of the current progress through automatic status messages.

3. EDI onboarding for suppliers

A special component of digital supplier onboarding is the connection via EDI (Electronic Data Interchange). EDI makes it possible to exchange business documents such as orders, delivery bills or invoices in standardized formats without the need for manual input. Further information on EDI standards is provided by GS1 Germany, the official organization for data and communication standards in retail.

3.2 Advantages of EDI onboarding

- Significantly accelerated integration of new suppliers

- Reduction of transmission errors

- Improved data quality through standardized formats

- Greater transparency and traceability

3.3 Steps in the EDI onboarding process

The process includes the technical connection to the company’s EDI system, validation of the formats with the help of test runs and the live connection. Accompanying monitoring ensures that communication between the company and suppliers functions reliably.

4. simplified communication and up-to-date data

Once the onboarding process is complete, companies benefit from simplified communication channels and constantly updated data. Integrated supplier management software serves as a central platform for the exchange of information. Status messages, automatic notifications and transparent dashboards ensure that everyone involved is always informed about the current status. Queries can be processed more efficiently and problems solved more quickly. This significantly reduces costs and time expenditure while increasing data quality.

5. efficiency and transparency through digital onboarding

Digitally supported onboarding brings decisive advantages for companies:

- Automated processes reduce the administrative workload.

- Transparent checklists make tracking easier.

- Integrated workflows create uniform standards.

- The direct ERP connection accelerates supplier integration.

- Centralized data management increases transparency throughout the entire supply chain.

In addition, a close connection to areas such as supplier evaluation, supplier development and key figures & reporting supports the continuous improvement of supplier relationships. An integrated supplier portal also enables transparent communication and direct data exchange with partners. Achieve further optimizations through improved management of product groups and articles as well as e-procurement and webshop integration.

The German Association of Materials Management, Purchasing and Logistics (BME) offers further guidelines and practical information on process optimization and purchasing organization. The international standard ISO 9001 is relevant for more in-depth quality management aspects.

6 Conclusion: Supplier onboarding as a success factor

Sophisticated supplier onboarding saves time and money, improves data quality and ensures that quality and compliance standards are met from the outset. Companies that rely on modern software solutions such as SC-Manager benefit from automated processes, uniform standards and a transparent database. Supplier onboarding is thus transformed from an administrative obligation into a strategic success factor in supply chain management.

For further information on the legal framework, the Federal Ministry for Economic Cooperation and Development (BMZ ) provides official explanations of the Supply Chain Due Diligence Act (LkSG). The UN Global Compact also provides international guidelines for sustainable corporate governance.

7. Frequently asked questions (FAQ)

What is supplier onboarding?

Supplier onboarding refers to the structured process of integrating new suppliers into company systems and processes. The aim is to ensure efficient, transparent and compliant collaboration.

What are the benefits of digital supplier onboarding?

Digital solutions automate checks, speed up processes and reduce errors. Companies benefit from time savings, compliance security and better data quality.

How does the supplier onboarding process work?

The process includes registration, self-assessment, verification, approval and integration into ERP systems – supported by automated workflows and real-time data.

What role does the SC Manager play in supplier onboarding?

The SC-Manager automates and centralizes all onboarding processes – from recording and checking to integration into existing systems.

How does SCM software support the onboarding process?

SCM software offers workflow control, documentation, reporting and API interfaces for an end-to-end, digital supplier onboarding process.