1. purchasing KPIs as the basis for strategic management

Key purchasing figures are a central instrument for strategically managing purchasing and making well-founded decisions. This is because a transparent view of the purchasing processes can only be gained through the systematic recording and evaluation of these key figures by a purchasing controlling department. Performance and process-related key figures are also known as key performance indicators (KPIs).

They not only increase the traceability of services, but also create targeted starting points for optimizing processes. At the same time, KPIs form the basis for continuous improvement and the scalability of the purchasing organization. It is crucial that the selection and weighting of the relevant KPIs is closely linked to the overarching purchasing strategy in order to set the right priorities and achieve sustainable success.

Rule of thumb: Strategic KPIs show where procurement is heading – operational KPIs show how well procurement is working today.

2. operational purchasing key figures measure daily processes and efficiency

Operational purchasing KPIs are indispensable when it comes to making day-to-day purchasing work efficient, transparent and controllable. This is because they make the performance of individual processes measurable and allow you to react immediately to changes. Especially in a dynamic market environment, it is crucial to be able to access real-time data in order to recognize cost changes at an early stage and implement operational adjustments immediately.

In addition, operational key figures in purchasing can be specifically linked to strategic KPIs so that the implementation of long-term planning is supported by concrete operational measures. In this way, they act as a link between strategic alignment and operational action.

Whether it is the management of ordering processes, supplier performance or payment terms – operational KPIs in procurement provide concrete indications of where there is potential for optimization. In particular, the order volume and adherence to payment terms have a direct impact on operational efficiency. They influence process costs, liquidity and supplier relationships. Overall, operational KPIs therefore make a decisive contribution to making procurement flexible, targeted and efficient.

Below you will find an exemplary overview of operational KPIs in purchasing.

2.1. KPI for ordering processes

A key area of operational KPIs is the analysis of ordering processes. By regularly recording the following KPIs, efficiency potential can be identified and process stability ensured:

- Number of orders per period: Provides information about the order volume and can serve as a basis for evaluating workload or automation requirements.

- Average procurement time (lead time): Shows how long it takes on average for an order to be triggered and completed – a key performance indicator for process speed.

- Proportion of eProcurement orders: This figure illustrates the extent to which digital systems are used in the procurement process and how automated purchasing already is.

- Average order processing time: Helps to identify bottlenecks in order processing and uncover potential for improvement.

- Maverick buying rate: Measures how often purchases are made outside the defined processes – an important indicator of compliance and process discipline.

2.2. Key figures for logistics

In addition to the ordering processes, logistics plays an equally crucial role in operational purchasing, as it has a significant influence on security of supply:

- Adherence to delivery dates in %: Shows how reliably suppliers meet the agreed delivery dates – the higher the value, the more stable the supply chain.

- Delivery reliability in %: Indicates whether the quantity delivered matches the quantity ordered – deviations can lead to production bottlenecks.

- Backlog rate for orders: Records the proportion of open or delayed orders and serves as an early indicator of disruptions in the delivery process.

2.3. Key quality figures

Quality indicators in purchasing are particularly important because they allow conclusions to be drawn about the reliability of suppliers and the quality of the goods delivered. This is because faulty deliveries cause rework, delays and additional costs:

- Goods receipt deviations (e.g. in quantity or quality): Show the frequency of differences between order, delivery bill and actual goods.

- Complaint rate: Indicates how many deliveries had to be rejected – a direct quality indicator of supplier performance.

2.4. KPI for invoices and payments

The phase after goods receipt also offers valuable key figures, as deviations in invoices or payments affect both cooperation with suppliers and internal efficiency:

- Payment behavior towards suppliers: Measures compliance with payment terms and the use of cash discounts. A high degree of compliance promotes stable supplier relationships and improves the key financial figures.

- Price discrepancy between order and invoice: This KPI shows how often invoices do not match the agreed prices – a possible indication of contract discrepancies or system errors.

3. strategic purchasing indicators as management tools

Strategic purchasing KPIs are of central importance when it comes to aligning purchasing in a long-term and targeted manner. This is because they help to make overarching goals such as cost reduction, transparency and value creation measurable and to manage them in a targeted manner. The focus here is particularly on KPIs such as purchasing volume or total cost development, as they allow direct conclusions to be drawn about the performance and strategic direction of purchasing.

At the same time, these key figures influence the long-term corporate strategy by ensuring that procurement decisions are not only economical in the short term, but also make a sustainable contribution to the company’s success. Another key aspect is supplier evaluation, as a reliable and strategically selected supplier base is crucial for a stable and cost-efficient supply chain. Below you will find an exemplary overview of strategic key figures in purchasing.

3.1. Purchase volume

The purchasing volume is one of the central strategic key figures in purchasing because it serves as a benchmark for purchasing performance and provides important management impulses. It describes the total value of all goods and services purchased by the company within a certain period of time.

To calculate the purchasing volume, all relevant procurement expenditure is added together, often broken down by product group, region or supplier. This type of classification is useful for carrying out targeted analyses, recognizing regional focuses and identifying purchasing potential.

The share of strategic suppliers in the total volume is of particular interest, as this allows conclusions to be drawn about the dependence on core partners and the stability of the supply chain. At the same time, a high purchasing volume has a direct influence on negotiating power with suppliers, as larger purchase volumes often lead to better conditions. Last but not least, the proportion of long-term contracts in the total purchasing volume also plays an important role – because the higher this is, the more stable and predictable the purchasing conditions are over time.

3.2. Cost reduction in purchasing

Reducing costs is a core strategic task of procurement because it makes a decisive contribution to competitiveness and increasing efficiency. It is not just about short-term savings, but above all about reducing the total cost of ownership (TCO) – i.e. the total costs over the entire life cycle of a product or service.

Regular analyses of cost changes are therefore essential in order to plan budgets realistically and optimize them in a targeted manner. At the same time, there is a close correlation between cost reduction and supplier performance: only efficient and quality-conscious suppliers make it possible to work economically in the long term without having to accept quality losses or delivery risks.

Strategically aligned cost ratios therefore make a significant contribution to securing the company’s long-term success.

3.3. Key figures on contracts and the supplier base

Strategic purchasing takes into account not only prices and quantities, but also the quality and stability of supplier relationships. Contractual regulations such as payment terms play an important role here, as they can influence both the company’s liquidity and supplier satisfaction.

Another important indicator is the degree of consolidation of the supplier base – i.e. the extent to which purchasing volumes are concentrated on a few strategically selected suppliers. Greater consolidation can increase efficiency and negotiating power, but also harbors dependency risks.

The negotiation rate for large tenders provides information on the extent to which purchasing is actively managing and exploiting cost optimization potential. At the same time, the financial stability of suppliers should always be taken into account in order to identify risks in the supply chain at an early stage.

Tools such as a supplier development index, for example via scorecards, help to objectively assess and continuously improve the performance and potential of suppliers. In summary, it can be said that the degree of fulfillment of strategic purchasing targets, for example as part of a balanced scorecard, is also a key indicator of the success of the overall purchasing strategy.

3.4. Key figures on sustainability and innovation

Modern purchasing strategies are increasingly geared towards future viability, which includes both sustainability and the ability to innovate.

The degree of innovation of suppliers, measured for example by the number of new technologies or product developments, is a strategic KPI that shows how much purchasing contributes to the company’s innovative strength. After all, only those who work with progressive partners can hold their own in the market in the long term.

At the same time, sustainability indicators are becoming increasingly important in purchasing – for example, the carbon footprint of supply chains or the use of environmentally friendly materials, regulated by the Supply Chain Duty of Care Act, among other things. These KPIs are not only an expression of social responsibility, but are also increasingly relevant for customer requirements, legal requirements and corporate image. This makes it clear that strategic purchasing figures are far more than just numbers – they are key management tools for safeguarding the future and competitiveness.

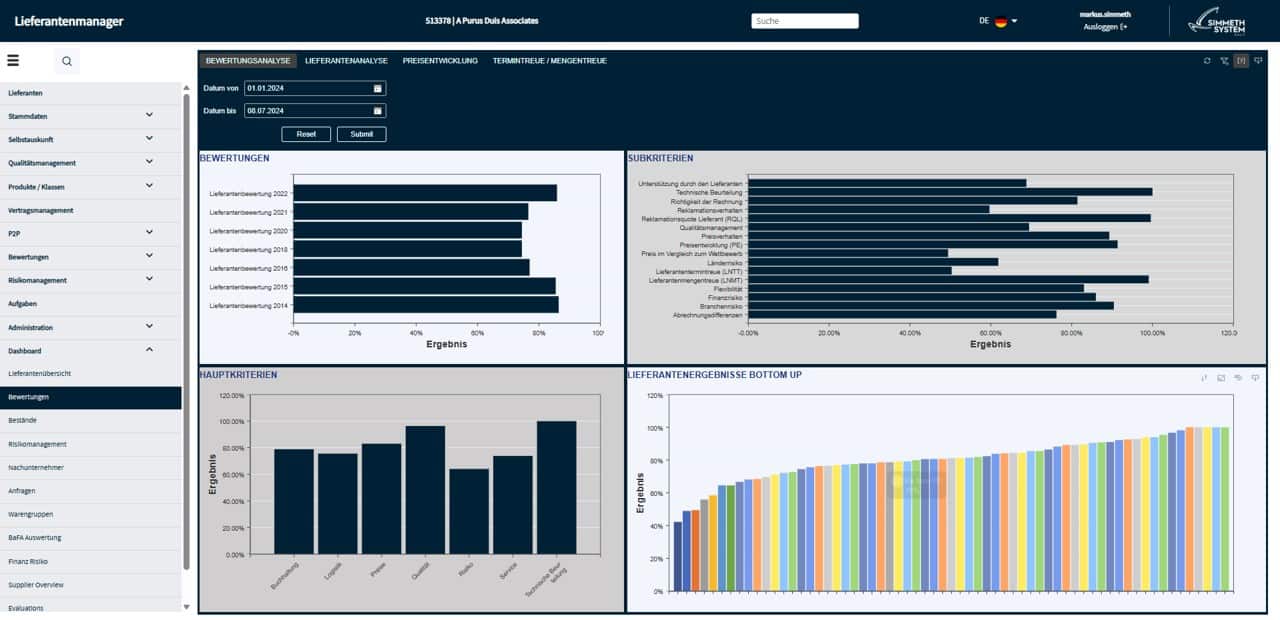

4. supplier evaluation and supplier performance

The systematic evaluation of suppliers is a central element of strategic purchasing, as it ensures that not only short-term price advantages, but also long-term partnerships and stable supply chains are guaranteed. A holistic supplier evaluation is ideally carried out using a scorecard that links both operational and strategic KPIs. This creates a comprehensive picture – a so-called 360-degree assessment – that reflects a supplier’s performance, reliability and development potential.

Operational KPIs in particular, such as on-time delivery or the compliance rate (adherence to guidelines and contracts), play a decisive role here because they provide direct information about practical cooperation. A supplier who regularly delivers late or incompletely not only causes delays, but also jeopardizes the entire process chain. Strategic KPIs, on the other hand – such as innovative strength, sustainability or quality – show whether a supplier will also meet the company’s requirements in the long term.

Supplier performance also has a strong impact on the structure of payment terms. This is because only reliable and financially stable suppliers may receive longer payment terms or other benefits, while weaker performance may require stricter payment terms to minimize risk. Performance and payment terms therefore directly influence the quality and stability of the collaboration.

Typical KPIs for measuring supplier performance in purchasing include

- Adherence to delivery dates (%): Percentage of deliveries made punctually on the agreed date

- Delivery reliability (%): Degree of conformity between ordered and delivered quantity

- Quality indicators: e.g. number of complaints or incoming goods deviations

- Response time to requests and escalations

- Fulfillment of compliance requirements (e.g. certifications, sustainability guidelines)

Overall, a structured supplier evaluation enables the purchasing department to identify risks at an early stage, initiate targeted development measures and at the same time build stable and efficient supplier relationships.

5. reporting: from measuring to optimizing key procurement figures

Professional reporting is far more than just a documentation of figures – it is a central management tool that enables purchasing managers to identify inefficiencies at an early stage and take targeted countermeasures. Because only those who measure regularly can optimize in a targeted manner. Through the targeted use of reporting, weak points in the processes can be made visible before they have a negative impact on quality, costs or deadlines.

Another important success factor is the standardization of KPIs to enable consistent and comparable reporting across all product groups, departments and locations. This not only increases internal transparency, but also significantly improves decision-making at all levels. In addition, meaningful reporting makes a decisive contribution to improving cross-departmental communication. If purchasing, finance and logistics departments have access to the same data and develop a common understanding of key figures, decisions can be made more quickly, on a more sound basis and in the interests of the company as a whole.

5.1. Reporting tools in purchasing

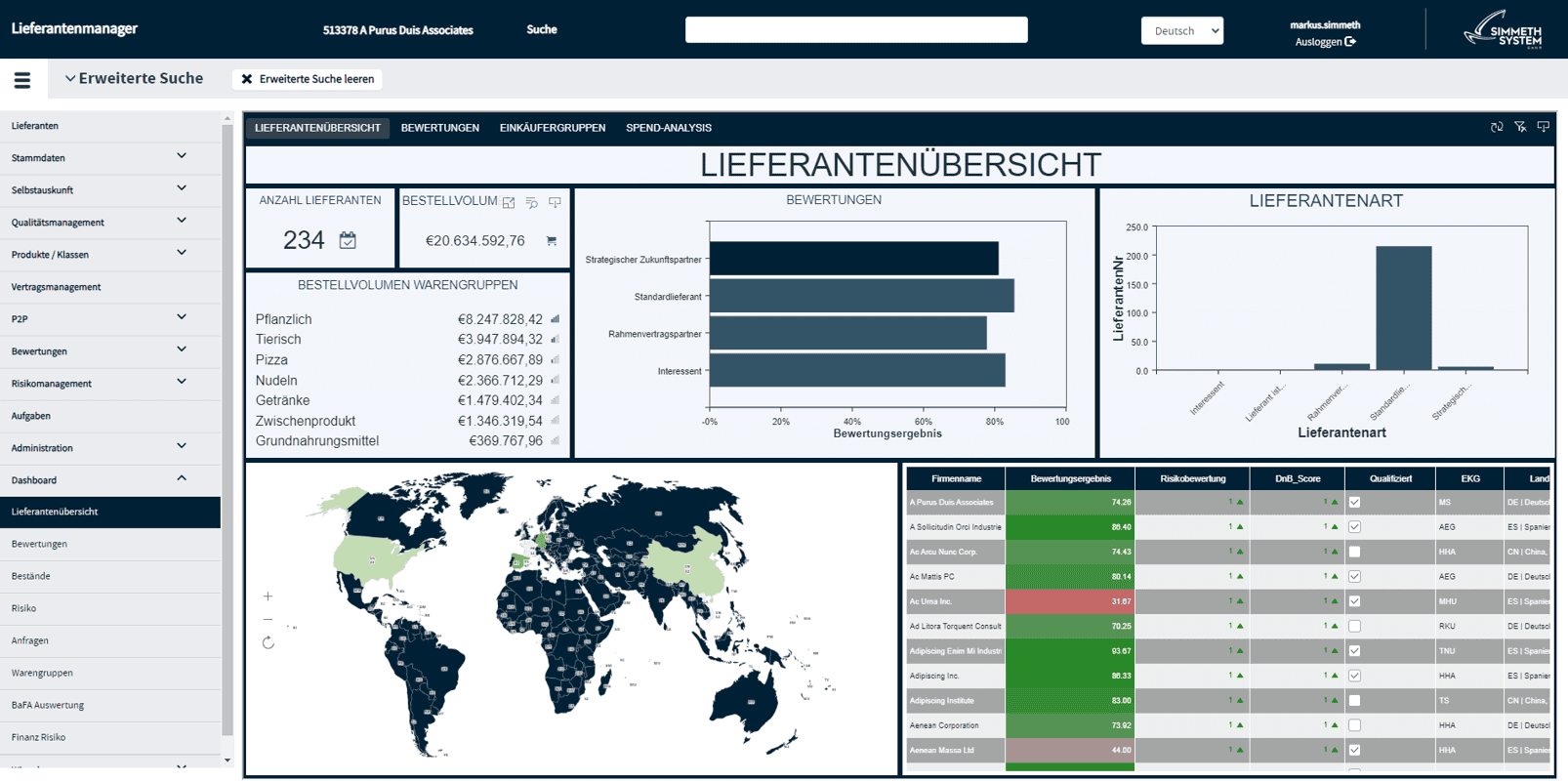

Modern reporting tools are indispensable for the effective management of purchasing, as they prepare current key figures quickly, precisely and in a user-friendly way. Dashboards and automated reporting systems in particular enable a flexible, role-based view of the most important KPIs.

The use of KPI dashboards makes it possible to track developments such as cost trends, supplier performance or order quantities in real time. As a result, decisions can be made based on data and measures can be initiated more quickly.

At the same time, key purchasing figures can now be seamlessly integrated into automated reporting systems that regularly create reports, highlight deviations and generate recommendations for action – without manual processing.

5.2. Interactive dashboards for analysis and optimization

Interactive dashboards offer numerous advantages over static reports. They not only enable real-time analysis of important key figures in purchasing, but also targeted troubleshooting and optimization along the entire supply chain.

For example, adherence to delivery dates and payment targets can be analyzed directly in the dashboard in order to quickly identify delivery bottlenecks or payment defaults. The automation of such dashboards saves time, reduces sources of error and at the same time significantly improves the purchasing department’s ability to react.

In addition, the visualization of purchasing data makes complex correlations understandable – such as the influence of supplier behavior on order volumes or the effect of late payments on the overall cost structure. This actively supports the optimization of processes.

5.3. Professional reporting for increased efficiency

Professional reporting makes a significant contribution to increasing efficiency in purchasing, as it saves valuable resources, reduces manual effort and improves transparency. Automated reports that are generated cyclically ensure that decision-makers always have access to up-to-date and consistent data.

For example, automated supplier reports enable better collaboration because they regularly reflect performance and identify potential for improvement – which in turn forms the basis for stable business relationships and targeted cost avoidance.

In addition, structured reports should be prepared regularly to disclose purchasing costs and savings achieved. Such reports not only increase transparency, but also the acceptance of strategic measures throughout the company. Modern software solutions also enable the seamless integration of KPIs across different departments so that purchasing, controlling and management can always work with a consistent level of information.

5.4. Artificial intelligence AI and automated data integration

Artificial intelligence (AI) opens up completely new possibilities for purchasing controlling – particularly in the area of forecasting models and error prevention. By using intelligent algorithms, not only can historical data be evaluated, but future developments can also be predicted, such as price increases or delivery risks.

The automated integration of supplier and order data plays a central role here, creating an error-free and traceable database. In the area of payments in particular, the integration of payment target data ensures that payment processes are controlled automatically and systematic errors – such as late payments or double bookings – are avoided at the same time.

In addition, improved communication across systems – combined with automated data processing – makes a decisive contribution to cost avoidance, as media disruptions and manual intervention are reduced. Nevertheless, the challenge of continuously adapting automation processes to new business requirements remains. Only if systems are flexible and grow with the company can the full potential of digital purchasing optimization be exploited.

6. best practices: Using purchasing key figures to optimize purchasing

The targeted use of purchasing KPIs is far more than just a control mechanism – it is the basis for modern, proactive and value-oriented procurement. Regular audits of key purchasing figures help to identify potential weaknesses at an early stage and at the same time take action before operational or strategic problems arise.

Benchmarking also plays an important role in evaluating your own purchasing performance in comparison to other companies or industry averages. This allows realistic targets to be defined and optimization potential to be identified. An often underestimated success factor is the continuous training and development of employees in dealing with KPIs. Only if the entire purchasing team understands which KPIs are crucial and how they are interpreted can data-based management achieve its full effect.

6.1. Efficient process optimization through key figures

Purchasing KPIs provide a solid foundation for the systematic improvement of procurement processes. Through the targeted evaluation of KPIs, process steps can be assessed, bottlenecks identified and improvement measures derived.

A central component of this optimization is the regular review of cost changes and purchasing volumes. This is because continuous monitoring is the only way to identify trends and make well-founded decisions on adjusting quantities, suppliers or conditions. The payment target can also be used as an active control instrument to ensure the financial health of the purchasing department. Both liquidity advantages and better conditions can be achieved through targeted coordination with the finance department.

6.2. Measures in the event of deviations in KPIs in purchasing

Deviations in key purchasing figures are not necessarily negative – they provide valuable indications of where action is needed. However, it is important to react quickly and in a targeted manner.

For example, a decline in on-time delivery requires immediate action: In such cases, purchasing managers should adapt processes, work more intensively with affected suppliers and, if necessary, revise buffer times in logistics.

When purchasing costs rise, purchasing departments should take targeted countermeasures and consistently pursue cost reduction as an ongoing task. Renegotiations, alternative sources of supply or internal efficiency measures can be used to exploit leeway even in tight markets. Companies must also be prepared for increasing order volumes – as they can place a heavy burden on the process landscape. In such cases, automation solutions and the consolidation of orders are important levers for maintaining efficiency and realizing economies of scale.

6.3. Regular management based on key figures

Regular, KPI-based management is one of the best practices in modern purchasing. KPI-based management meetings with suppliers play a central role here, as they create transparency, promote a common goal orientation and strengthen the partnership.

At the same time, transparent reporting to internal stakeholders is essential. Regular updates on key purchasing figures, savings achieved and planned measures create trust and enable management to play an active role in shaping the company. Last but not least, the continuous monitoring of key purchasing figures forms the basis for ongoing process and cost optimization. This creates a cycle of measuring, evaluating, acting and improving – the foundation for efficient and future-proof purchasing.

7. successful in purchasing with key figures

Today, effective purchasing controlling is no longer based solely on empirical values, but also on reliable data and precise analyses. The long-term implementation of KPIs is far more than just a reporting tool – it forms the core of a culture of continuous improvement in purchasing. Only if KPIs are an integral part of daily management can procurement react flexibly to changes and act strategically at the same time.

It is also essential to regularly adapt the key figures used to changing market conditions and corporate goals. After all, what was relevant yesterday may be outdated tomorrow. Only with dynamic, adaptable KPIs can procurement remain fit for the future. After all, purchasing KPIs only develop their full potential if they are closely linked to the overarching corporate objectives. This connection creates a holistic strategic orientation and makes purchasing an active value driver in the company.

7.1. Use of purchasing key figures for the corporate strategy

Key figures in purchasing make a significant contribution to long-term cost reduction and the targeted management of purchasing volumes. By making potential savings visible and making performance measurable, they actively support the economic orientation of the company.

7.2. Optimization of supplier relationships

The targeted measurement of supplier performance using KPI-based evaluation systems not only promotes transparency, but also trust and reliability. On this basis, partnerships can be actively shaped and jointly developed.

Payment targets can be used specifically as a strategic instrument – for example, to strengthen long-term relationships or to retain preferred suppliers. In addition, consistent measurement of the compliance rate ensures greater transparency in supplier management and, at the same time, more efficient compliance with standards and specifications.

7.3. Long-term increase in efficiency with key figures in purchasing

Purchasing key figures are not only short-term control variables, but also serve as reliable indicators for sustainable cost avoidance and process optimization throughout the entire supply chain. They form the basis for strategic decisions and support companies in establishing a future-proof purchasing strategy.

Sustainable competitive advantages can be achieved in particular through the combination of cost reduction and intelligent volume management. In addition, professional payment target management helps to secure healthy cash flows and ensure stable business relationships – a key building block for long-term success in purchasing.