Supplier self-disclosure: templates and legal information

1. Supplier self-disclosure – what is it?

Supplier self-disclosure is a systematic self-disclosure by suppliers in which they provide key business data in a structured manner. This is not just a formal query, but a central tool in quality management – particularly in accordance with the requirements of ISO 9001 and the VDA requirements. (See also our “Overview: relevant standards and legal requirements for supplier self-disclosure” further down in the text)

The targeted collection of information, for example on certifications, company structure or sustainability measures, creates a sound basis for decision-making. The supplier self-assessment thus serves both the selection and the evaluation and risk assessment of suppliers. It is therefore an indispensable part of a holistic supplier assessment and contributes significantly to transparency and security in the supply chain.

2. Structure of the supplier self-disclosure

The structure of the supplier self-disclosure is divided into several sections that are coordinated in terms of content and cover both general and specific information about the supplier. This provides a comprehensive picture of the potential business partner’s performance, reliability and sustainability. The individual components are logically structured to enable efficient processing and evaluation.

2.1. Supplier self-disclosure form – general part

In the general part of the form, basic company data is requested first. This includes the name of the company, the address, contact person and the respective legal form. In addition, information on the company structure, existing branches and possible group affiliation is collected. Proof of valid certificates – for example, ISO 9001 or environmental standards – must also be enclosed to demonstrate the supplier’s quality and environmental expertise.

2.2. General part of the supplier self-disclosure

In the general section of the self-disclosure, all basic company data is systematically recorded again. This includes the name, address, central contact person and the legal form of the company. Information on the company structure, subsidiaries and other locations is also requested. This section is rounded off by the submission of certificates such as ISO 9001 or valid environmental standards, which prove compliance with relevant standards. This data forms the basis for an initial assessment of the supplier and enables a structured comparison of different providers.

2.3. Fill out supplier self-disclosure form – Specific information

This is followed by the specific part of the self-disclosure. Here, detailed information is required on the products offered, the respective production sites and the available capacities. Depending on the industry and product group, information on typical delivery times, the returns rate and the logistics processes used is also relevant. Sustainability issues also play a central role: information on CSR(Corporate Social Responsibility) measures, environmental protection and sustainable practices in the supply chain are therefore an integral part of this section. This ensures that non-economic criteria are also included in the assessment.

2.4. Supplier self-disclosure and supplier questionnaire

Supplier questionnaires are often used as part of the self-disclosure. These are either part of the self-assessment or are provided as a separate document. While the supplier questionnaire usually has a standardized structure and contains clear specifications, the self-assessment offers more scope for individual descriptions and company-specific additions. Nevertheless, both instruments pursue a common goal: they support supplier qualification and at the same time serve as a basis for a well-founded risk assessment within the supply chain.

2.5. Structured supplier self-assessment via a supplier portal

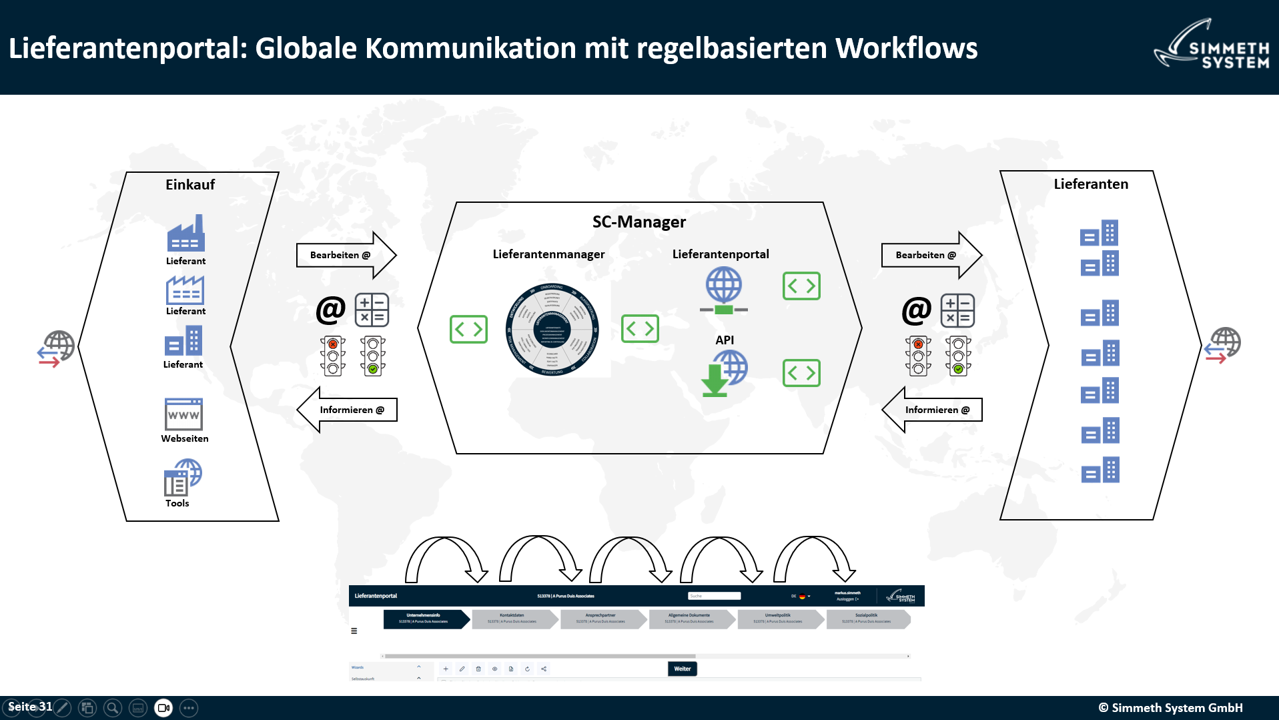

Modern supplier management software such as Simmeth’s SC-Manager offers the option of efficiently processing supplier self-assessments via a digital supplier portal . Integrated templates for supplier questionnaires can be filled out directly in the system, which significantly reduces the effort for both sides.

The structured online processing via a supplier portal enables easy handling and speeds up data entry and the approval process. At the same time, the system can be flexibly adapted to company-specific requirements – for example through industry-specific questions or additional evaluation criteria. This makes the entire supplier qualification process not only more efficient, but also more transparent and sustainable.

3. Legal requirements for supplier self-disclosure

Even if supplier self-disclosure appears to be a purely organizational tool at first glance, in practice it is subject to various legal and normative framework conditions. Although these do not necessarily result from specific laws, the legally compliant design plays a central role, particularly in connection with industry-specific standards, certifications and data protection regulations.

3.1. Mandatory supplier self-disclosure – when is it necessary?

In principle, there is no legal obligation to carry out a supplier self-assessment. Nevertheless, it is an established and expected practice in many industries – especially in the context of business initiation and supplier onboarding. Corporations, public sector clients and companies with critical or complex supply chains often require a self-disclosure as a prerequisite for cooperation.

This usually involves going through a structured supplier onboarding process that is integrated into supplier management software solutions such as SC-Manager. Only after successful qualification can a potential supplier be stored there as an official vendor.

It is also necessary in many cases in order to reliably fulfill quality management requirements, such as ISO 9001 certification or process documentation.

3.2. Supplier self-disclosure and GDPR

With regard to the General Data ProtectionRegulation (GDPR), certain principles must be observed when collecting and processing supplier data. For example, only necessary and relevant data may be collected and stored. In addition, companies are obliged to inform their suppliers transparently about the purpose, scope and legal basis of data processing. If personal data – such as that of contact persons – is processed, a legally secure basis is required, for example in the form of a legitimate interest or consent. This is the only way to ensure that self-disclosure complies with data protection regulations.

3.3. Relevant standards and legal requirements for supplier self-disclosure

Even if there is no direct legal obligation to provide supplier self-disclosure, recognized standards such as ISO 9001, VDA 6.3 or the German Supply Chain Duty of Care Act require structured and comprehensible information about suppliers. In regulated industries such as medical technology or the automotive industry, self-disclosure is therefore de facto mandatory in order to pass audits, certifications or compliance requirements. For this reason, it is advisable to update the self-disclosure on a regular basis in order to permanently fulfill both legal and formal requirements.

3.4. Overview: relevant standards and legal requirements for supplier self-disclosure

| Standard | Relevance | Expectations |

|---|---|---|

| 1. ISO 9001 (quality management) | Internationally recognized standard for quality management systems | – Systematic supplier evaluation is required – Self-assessment serves as a basis for selection and monitoring – Documentation and traceability |

| 2. VDA 6.3 (process audit automotive industry) | Industry standard for evaluating processes in the automotive supply chain | – Detailed information on processes, locations, capacities – Evidence of quality and environmental standards – Supplier performance is regularly evaluated |

| 3. IATF 16949 (Automotive QMS) | Extension of ISO 9001 for the automotive industry | – Comprehensive supplier evaluation is mandatory – Continuous improvement and risk assessment – Self-disclosure documentation recommended |

| 4. EN ISO 13485 (medical technology) | Quality requirements for manufacturers and suppliers of medical products | – Risk-based supplier selection – Documented proof of performance required – Supplier qualification must be verifiable |

| 5 AS/EN 9100 (aerospace) | Quality management for the aerospace industry | – Structured supplier evaluation mandatory – Performance and risk data must be regularly checked and documented |

| 6. IRIS / ISO/TS 22163 (railroad industry) | QM standard for rail suppliers | – Supplier information on quality and capacity – Scoring or evaluation system required – Self-disclosure as part of audit preparation is standard practice |

| 7th LkSG (Supply Chain Due Diligence Act) | German law on human rights and environmental obligations in supply chains | – Risk analysis along the supply chain – Documented self-disclosure on CSR and environmental aspects – Documentation and reporting obligation |

| 8. SA8000 (Social Accountability Standard) | Social standard for fair working conditions along global supply chains | – Information on labor rights, human rights and social practices – Proof of self-disclosure required |

| 9. ISO 14001 (environmental management) | Environmental management standard with significance for sustainable procurement | – Information on environmental targets, measures, resource consumption – Proof of environmental certificates via self-disclosure |

| 10. BRC / IFS (food / packaging) | Safety and quality standards for the food and packaging industry | – Risk and performance assessment of suppliers – Use of self-disclosure for traceability and supplier approval |

| 11. GMP (Good Manufacturing Practice) | Mandatory standard in the pharmaceutical, cosmetics and food industries | – Validation and control of supplier processes – Documented supplier information through self-disclosure or audit |

Note on the standards and legal requirements

Even if not all of these standards explicitly require supplier self-disclosure in their wording, in practice it is a common and often indispensable tool for meeting the respective requirements and making them auditable. Companies that are certified according to one of these standards or are working towards this are therefore well advised to obtain a structured and regularly updated self-disclosure from their suppliers.

4. What templates are available for supplier self-disclosure

To ensure that supplier self-disclosure can be implemented efficiently, there are various template formats that can be used depending on the size of the company, digital infrastructure and complexity of the supply chain. Whether as a simple Word file, a structured Excel spreadsheet or a professional, integrated software solution – it is important that the template is adapted to the specific requirements of the company and designed to be practical.

4.1. Supplier self-disclosure template Word

Word templates are used in companies that need an uncomplicated and flexibly adaptable solution. They can be easily edited and tailored to individual requirements – either by adding industry-specific questions or by adapting them to internal standards. In addition, the Word template can be easily converted into a PDF after completion, which enables audit-proof archiving. Smaller companies without their own digital system in particular benefit from this accessible solution. However, it should be noted that the effort per supplier is very high and therefore this is no longer an efficient method for a larger number of suppliers.

4.2. Supplier self-disclosure template Excel

Companies that want to carry out a systematic evaluation and supplier assessment prefer to use an Excel template. This offers significantly more structure than Word. In the spreadsheet-based presentation, you can filter, sort and evaluate the recorded information efficiently – using scoring models, for example. Excel also enables simple automation, for example for calculating risk levels or graphically evaluating returns. Purchasing departments or companies that regularly carry out audits therefore often rely on Excel templates. However, it should be noted that this manual solution with Excel can become confusing once a certain number of suppliers and internal participants are involved. It should therefore be seen as a solution for small companies or as a preliminary stage to a professional solution such as Simmeth’s supplier management software.

4.3. Professional software solution for supplier self-disclosure

Providers such as Simmeth System offer professional SRM software that includes integrated supplier self-disclosure, standardized supplier questionnaires and complete onboarding processes. These are conveniently handled via a digital supplier portal, which enables suppliers to submit all the required information in a structured and efficient manner. This makes work considerably easier for purchasers: with the help of integrated checklists, they can keep track of the qualification status at all times and initiate targeted measures. In addition, the solution can be flexibly adapted to the company’s individual requirements – from the questionnaire structure to the evaluation system.

4.4. Free templates for supplier self-disclosure

Some providers, such as Simmeth System, provide free sample forms that can serve as a starting point for your own supplier self-disclosure. These pre-structured templates not only offer valuable time savings, but often already contain tried and tested content and instructions for completion. Especially in the introductory phase of a supplier qualification process, such free templates provide valuable support and facilitate the introduction of systematic supplier management.

4.5. Customize supplier self-disclosure templates

Regardless of the chosen format, it is important to customize each supplier self-disclosure – in particular to the respective industry, company size and the type of products or services purchased. A clear separation between general company information and specific performance characteristics makes subsequent evaluation much easier. Companies can also integrate the completed self-disclosure form into a digital supplier management system. This allows them to manage, update and track the information more efficiently and professionally.

5. Targeted query of supplier self-disclosure on sustainability

Sustainability is becoming increasingly important in the supply chain – not only due to legal requirements, but also due to the changing expectations of customers, business partners and investors. A targeted query of sustainability aspects within the supplier self-disclosure helps companies to create transparency, identify risks and systematically implement their ESG strategy. The following sections show how sustainability can be taken into account in a structured way in the self-disclosure.

5.1. Sustainability criteria in the supplier self-disclosure

In order to promote sustainable supply chains, specific sustainability criteria should be integrated into the supplier self-disclosure. This includes, for example, information on existing environmental management, resource conservation and recording the carbon footprint. Equally important is information on social standards along the supply chain, such as fair working conditions, working time regulations or compliance with human rights. In addition, international guidelines such as the UN Global Compact, the ILO core labor standards or the OECD Guidelines for Multinational Enterprises should be taken into account in order to map global standards uniformly.

5.2. Why sustainability is important in supplier self-disclosure

The integration of sustainability issues into supplier self-disclosure is so relevant because legal requirements – such as the Supply Chain Sustainability Act (LkSG) or EU directives on sustainability reporting – are constantly increasing. At the same time, there is increasing social pressure to assume responsibility across the entire supply chain. In addition, sustainability data is increasingly being incorporated into ESG reports and CSR certificates, which has become mandatory for many companies. Last but not least, a sustainable supply chain also offers a strategic advantage in the market, as it has a positive impact on the company’s image, strengthens customer trust and ensures long-term competitiveness.

5.3. Making supplier self-disclosure sustainable in practice

In the self-disclosure, companies should ask specific questions about environmental goals, existing certificates (e.g. ISO 14001, EMAS) and current or planned measures. In this way, they record sustainability not only symbolically, but also practically. In this way, they recognize particularly committed suppliers at an early stage and promote them in a targeted manner. At the same time, the structured survey enables an objective evaluation and differentiation of sustainable suppliers. In the long term, it is advisable to link the supplier self-disclosure with your own sustainability strategy in order to effectively implement ecological and social goals along the entire value chain.

6. Use supplier qualification checklist

Structured supplier qualification is essential in order to select reliable, efficient and compliant business partners, evaluate them on an ongoing basis and develop them methodically for a long-term business relationship. In addition to the supplier self-assessment via questionnaires, the use of a checklist that systematically records all relevant checkpoints is a good idea. This not only makes the qualification process more efficient, but also more transparent and comprehensible.

6.1. Important checkpoints in the checklist

The key contents of such a checklist initially include basic company data and existing certifications, such as ISO 9001 or environmental standards. In addition, aspects from the classic supplier evaluation, delivery performance, such as adherence to delivery dates and flexibility, as well as pricing and commitment to sustainability should also be taken into account. It is equally important to check compliance with legal and contractual requirements, for example with regard to labor law, data protection or due diligence obligations along the supply chain. A well-founded supplier decision can only be made if these criteria are systematically recorded and evaluated.

6.2. Supplier qualification checklist for supplier self-assessment

The checklist serves as a useful and structured supplement to the supplier self-disclosure form. While the self-disclosure form usually contains the information from the supplier itself, the checklist enables an internal, comparative evaluation of this data. It makes it easier to systematically assess and compare different suppliers – especially if several offers or new business partners need to be checked at the same time. In addition, it supports internal audits and quality management by guaranteeing comprehensible documentation of the evaluation steps.

6.3. Advantages of a standardized checklist

The use of a standardized checklist offers several advantages: Firstly, it creates a uniform evaluation framework that applies equally to all suppliers. This reduces subjective assessments and increases comparability. Secondly, standardization helps to increase efficiency, as recurring inspection processes are clearly structured and time-saving. Last but not least, the checklist helps to reliably record important aspects of supplier qualification and avoid gaps in the assessment process at an early stage.

6.4. Checklist and supplier evaluation

Both the checklist and the supplier evaluation are central tools in the context of supplier qualification – they pursue similar goals, but differ in structure and function.

Similarities

- Both are used for the structured collection and evaluation of relevant supplier information.

- They support decision-making processes in purchasing and quality management.

- Both checklists and assessments can be integrated into audits and risk analyses.

Differences

- The checklist is usually an operational tool for data collection and serves as preparation for the actual evaluation. It ensures that you do not overlook any important criteria.

- The supplier evaluation builds on the information collected and transforms it into a systematic overall assessment, often with the help of a points system, scoring or a risk classification.

- While checklists often examine qualitative and formal issues, supplier evaluation focuses more on performance assessment based on key figures such as delivery reliability, quality or complaint rates.

In combination, both tools enable a well-founded, comprehensible and objective assessment of suppliers – from initial qualification to regular reviews during ongoing business. Professional solutions such as Simmeth’s SC Manager integrate both checklists and evaluation mechanisms in a central system – and thus offer consistently efficient, transparent and auditable supplier qualification.

6.5. Exemplary checklist for supplier qualification

| CATEGORY | TEST POINT | COMPLETED Yes/No | NOTE |

|---|---|---|---|

| 1. company data & structure | – Commercial register entry / valid legal form available – Contact person named (incl. contact details) – Affiliation to group / subsidiary documented | J ☐ / N ☐ J ☐ / N ☐ J ☐ / N ☐ | |

| 2. certifications & standard security | – ISO 9001 certificate valid and submitted – Environmental certification (e.g. ISO 14001, EMAS) available – Other relevant standards (e.g. IATF 16949, SA8000) | J ☐ / N ☐ J ☐ / N ☐ J ☐ / N ☐ | |

| 3. products & services | – Product portfolio clearly described – Production sites listed – Production capacities sufficient for demand | J ☐ / N ☐ J ☐ / N ☐ J ☐ / N ☐ | |

| 4. logistics & service | – Delivery times documented and realistic – Return rate acceptable / data available – Delivery capability guaranteed for short-term demand | J ☐ / N ☐ J ☐ / N ☐ J ☐ / N ☐ | |

| 5. quality & performance | – Historical delivery performance (e.g. delivery reliability, complaints) available – Quality assurance measures described – Complaints processes defined | J ☐ / N ☐ J ☐ / N ☐ J ☐ / N ☐ | |

| 6 Sustainability & CSR | – CSR strategy or measures described – Environmental goals formulated / sustainability report available – Compliance with social standards in the supply chain ensured (e.g. UN Global Compact) | J ☐ / N ☐ J ☐ / N ☐ J ☐ / N ☐ | |

| 7 Legal & Compliance | – Compliance with legal regulations (e.g. LkSG) confirmed – Data protection (GDPR) taken into account – Anti-corruption guidelines in place | J ☐ / N ☐ J ☐ / N ☐ J ☐ / N ☐ |

7 Conclusion: Supplier self-disclosure is an important part of supplier management

Supplier self-assessment is a key tool in modern supplier management – not only for initial qualification and supplier onboarding, but also for the continuous evaluation of existing partners. Thanks to its structured and standardized collection of company and performance data, it provides a reliable basis for well-founded decisions.

On the one hand, it enables efficient supplier selection, as it brings together all relevant information at an early stage and thus creates the basis for a transparent and comprehensible decision. Secondly, it helps to minimize risk at an early stage by identifying potential weaknesses or uncertainties in terms of quality, capacity or compliance in advance.

In addition, self-disclosure ensures improved transparency in communication between companies and suppliers – which is particularly beneficial for audits and long-term partnerships. It also supports legal security, as it helps to systematically fulfill normative requirements such as those from ISO 9001, VDA 6.3 or the Supply Chain Duty of Care Act. Last but not least, it simplifies documentation as all relevant data is available in a structured form and can be traced or updated at any time. Overall, supplier self-disclosure therefore makes a significant contribution to professional, legally compliant and sustainable supplier management.

Would you like to find out more about our digital solution for supplier self-disclosure?