1. What is a supplier audit? – Definition & basics

A supplier audit is an important tool in quality management, as it enables companies to systematically evaluate the performance and reliability of their suppliers. The focus here is on ensuring compliance with quality standards, legal requirements and contractually agreed requirements.

The audit also helps to identify risks in the supply chain at an early stage and at the same time uncover potential for optimization.

Various activities are carried out as part of the audit process – starting with careful preparation and structured implementation on site, through to detailed follow-up and evaluation of the results. Any deviations are then documented and measures for improvement are defined together with the supplier so that sustainable quality assurance can be guaranteed.

2. Advantages of a supplier audit

A supplier audit has numerous advantages, as it pursues key objectives such as quality assurance and risk management along the entire supply chain.

2.1. Quality assurance

The structured review of processes and standards at suppliers creates better transparency, giving companies more control over quality, deadlines and costs. At the same time, the audit promotes a targeted increase in quality and supports the optimization of processes, both at the supplier and in the company itself.

2.2. Risk management

The audit also makes a significant contribution to minimizing risk by identifying potential weaknesses at an early stage and systematically eliminating them. This is particularly important with regard to compliance, i.e. adherence to legal and regulatory requirements. Furthermore, the supplier audit forms a basis for the strategic further development of supplier relationships – with the aim of promoting efficient partners in the long term and driving forward joint improvements.

2.3. Economic efficiency

Last but not least, there are also economic benefits, as stable and quality-conscious supplier relationships lead to lower error costs, higher delivery reliability and ultimately to more efficient overall value creation.

3. Types of supplier audits

Supplier audits can be divided into different categories, depending on who is carrying out the audit and what the focus is. This differentiation helps companies to select the right type of audit for their individual requirements.

3.1. External supplier audit vs. internal supplier audit

There is a fundamental distinction between external and internal supplier audits. External audits are carried out by independent, external auditors – for example from certification bodies or specialized service providers. This approach ensures particularly objective and neutral results, which is particularly advantageous when it comes to certifications or legal requirements.

In contrast, the internal supplier audit is carried out by the company itself. The main aim here is internal quality assurance, regular assessment of supplier performance, supplier evaluation and continuous process optimization. Internal audits are flexibly adaptable and can be easily integrated into existing quality management systems.

With regard to the audit focus, a distinction is also made between different types of audit, such as the product audit, which focuses on specific delivery parts, the system audit, which examines the entire quality management system, and the procedure or process audit, which specifically evaluates individual procedures and production processes.

3.2. Supplier audit by audit subject

In addition to the organizational form, a supplier audit can also be classified according to the content focus, the so-called audit subject. This refers to the specific aspects of the supplier that are to be audited.

A central area is quality management, which is concerned, for example, with whether the supplier complies with all necessary measures to ensure consistent product quality. Sustainability is becoming increasingly important: more and more companies are auditing their suppliers specifically with regard to ecological and social criteria in order to meet legal requirements and social expectations.

The VDA 6.3 supplier audit is a particularly well-established standard in the automotive industry. This is based on a standardized catalog of questions and places high demands on processes, quality assurance and risk assessment along the supply chain. The VDA 6.3 standard allows an objective and comparable assessment and is often a prerequisite for cooperation with OEMs (Original Equipment Manufacturers) or Tier 1 suppliers.

4. Supplier audit checklist – How a supplier audit works

A successful supplier audit requires structured planning and implementation, which takes place in several clearly defined steps. From preparation and the actual audit through to follow-up and action monitoring – each stage contributes significantly to the overall objective: a reliable supplier assessment and continuous improvement.

4.1. 8 steps for the supplier audit

A) Planning

1. supplier audit preparation & scheduling

Every audit begins with careful preparation. The first step is to define the audit objectives – i.e. what the audit is intended to achieve, for example ensuring quality standards or identifying weaknesses. At the same time, the framework conditions of the audit are defined, such as the scope, the area of application and the composition of the audit team. As soon as the basic content has been determined, the audit is scheduled. The audit date is set and the supplier concerned is informed of the audit at an early stage so that they can prepare accordingly.

2. Define supplier audit criteria

A central element of every audit is the selection of suitable audit criteria. This includes the identification of relevant quality, environmental or performance standards that apply to the respective supplier. These include normative requirements (e.g. ISO 9001) as well as industry-specific or internal company standards. In addition, the audit checklist should be adapted to the specifics of the respective supplier in order to provide practical findings.

3. create audit plan & checklists

A clear audit plan is essential for structured implementation. This defines which areas, processes or documents are to be audited and when. At the same time, a customized checklist is created, ideally as a PDF template, which systematically maps all the points to be checked. This makes evaluation and documentation during the audit much easier.

B) Implementation

4. Introductory meeting & start of audit

An introductory meeting is held with the supplier at the start of the audit. The audit objectives and expectations are explained, the procedure is presented and open questions are clarified. This discussion creates trust and ensures a common understanding of the upcoming audit process.

5. Supplier audit activities – implementation & evaluation

Now comes the core of the audit: the actual examination of the supplier processes. The auditors analyze production processes, documentation, quality controls and other relevant aspects. The assessment is carried out using the previously defined checklist and criteria – objectively, comprehensibly and based on facts.

6. Create supplier audit report

All results of the audit are documented in a structured audit report. This records both positive findings and deviations or deficiencies. To facilitate subsequent reuse, it is advisable to create the report in a standardized supplier audit template, e.g. as a PDF or Excel file.

7. Final discussion & development of measures

The results are discussed with the supplier in the final meeting. In addition to the pure findings, the focus here is on the development of specific measures that can be used to eliminate identified weaknesses and exploit potential for improvement. An action plan is drawn up, including deadlines and responsibilities.

8. Corrective measures & monitoring

After the audit, the implementation phase begins: the supplier implements the agreed corrective measures. The auditing company takes over the follow-up and checks at regular intervals whether the measures have been effectively implemented. This ensures that the supplier audit contributes to sustainable quality improvement in the long term.

4.2. Checklist template supplier audit

Here you will find an overview table of the checklist for a supplier audit, based on the eight main steps of the audit process. This table is suitable as a structured template for audit planning and implementation:

| Audit phase | Central task | Goal / Result |

|---|---|---|

| 1. preparation & scheduling | – Define audit objectives – Define framework conditions – Inform supplier | Clear objectives and transparent planning |

| 2. define criteria | – Identify relevant standards – Adapt criteria | Customized evaluation criteria |

| 3. create audit plan & checklist | – Schedule planning – Create individual checklist (PDF/Excel) | Systematic implementation is made possible |

| 4. introductory talk | – Explain audit objectives – Explain procedure – Clarify questions | Creating a basis of trust, smooth start |

| 5. implementation & evaluation | – Check processes, documents, standards – Evaluate results with checklist | Objective assessment of supplier performance |

| 6. create audit report | – Document results – Record deviations – Create audit report with template | Complete and comprehensible audit documentation |

| 7. final discussion & action planning | – Present results – Discuss improvements – Create action plan | Joint optimization, clear responsibilities |

| 8. corrective measures & monitoring | – Implement measures – Monitor progress – Check effectiveness | Sustainable improvement and supplier development |

5. Legal framework and standards

A supplier audit does not take place in isolation, but always within the framework of applicable legal and normative requirements. In order for it to be carried out effectively, comprehensibly and with legal certainty, companies must take both international standards and specific legal regulations into account.

ISO 9001 plays a particularly important role in this context, as it defines globally recognized requirements for quality management systems. Although a supplier audit is not usually used directly to obtain an ISO certificate, its structure and objectives are often based on the principles of the standard – in particular process orientation, continuous improvement and customer orientation. This makes the audit an effective tool for ensuring quality standards within the supply chain.

This contrasts with so-called certification audits, which are carried out by accredited certification companies such as TÜV SÜD or Germanischer Lloyd. While internal or external supplier audits primarily serve to evaluate and develop existing supplier relationships, certification audits aim to certify formal conformity with standards such as ISO 9001 or ISO 14001. For this reason, certification audits are more strictly regulated and require compliance with specific audit procedures.

In addition, legal requirements must also be complied with when conducting a supplier audit – particularly with regard to data protection laws such as the GDPR, product liability guidelines, contract law and industry-specific safety or environmental requirements. It must also be ensured that the auditors have the necessary expertise so that the audit can be carried out objectively, comprehensibly and in a legally sound manner.

Overall, it is clear that a professionally conducted supplier audit not only fulfills internal quality objectives, but also contributes to compliance with legal regulations, risk minimization and the strengthening of corporate responsibility.

6. Supplier audit questionnaire – Important audit questions

A well-structured questionnaire is at the heart of every supplier audit. The questionnaire provides a uniform and comprehensible basis for evaluation, reliably covers all relevant aspects and creates transparency for subsequent evaluation and development of measures. Users can either use it as a standardized questionnaire or adapt it specifically to the particularities of the respective supplier.

6.1. Supplier audit questionnaire – Important audit criteria

A supplier audit questionnaire typically covers several key areas that are critical to the supplier’s performance and reliability. The most common audit criteria include:

| Test area | Sample questions |

|---|---|

| Quality management | – Is there a documented QM system? – What certifications do you have? |

| Process reliability | – Are the production processes documented? – Are process changes monitored? |

| Delivery capability | – How is adherence to deadlines ensured? – How is capacity management regulated? |

| Documentation & traceability | – Can materials and components be traced? – Are there test protocols? |

| Employee qualification | – Which training measures are documented? – Is there an induction structure? |

| Environmental protection & sustainability | – Are legal environmental requirements complied with? – Is there a sustainability concept? |

| Compliance & Ethics | – Is there a code of conduct? – How is corruption prevented? |

| Complaints & improvement management | – How are complaints processed? – Is there a systematic root cause analysis? |

Depending on the audit focus, these questions can be weighted or expanded to include specific requirements.

6.2. Supplier audit questionnaire – Standardized questions for audits

Standardized questionnaires are often used to ensure a high level of comparability and transparency – especially for supplier audits as part of international standards or industry standards. A well-known example is the VDA 6.3 questionnaire, which is used in the automotive industry. It provides a structured assessment framework for topics such as project management, series production and supplier development.

Advantages of standardized questionnaires:

- Uniform evaluation basis for all suppliers

- Improved comparability across audits

- Greater objectivity in the evaluation

- Support in providing evidence to customers or authorities

If required, the standardized catalog can be supplemented with company-specific questions to reflect individual requirements.

Who normally carries out the supplier audit?

A supplier audit is usually carried out by internally trained auditors, quality managers or purchasing managers. In certain cases – such as with critical suppliers or as part of certification preparations – external auditors or specialists from third-party organizations (e.g. certification companies) are also called in.

Typical roles in the audit team:

| Role | Task |

|---|---|

| Audit manager:in | Overall responsibility, coordination, contact person for the supplier |

| Specialist auditors | Testing of specific processes (e.g. production, logistics, quality) |

| Secretary:in | Documentation of all results and statements |

| External consultant (optional) | Support with conformity to standards, objective assessment |

In summary, a well-founded catalog of questions contributes significantly to the quality and informative value of a supplier audit – both as a guideline for the implementation and as a basis for the evaluation and further development of the supplier relationship.

7. Digitize supplier audit

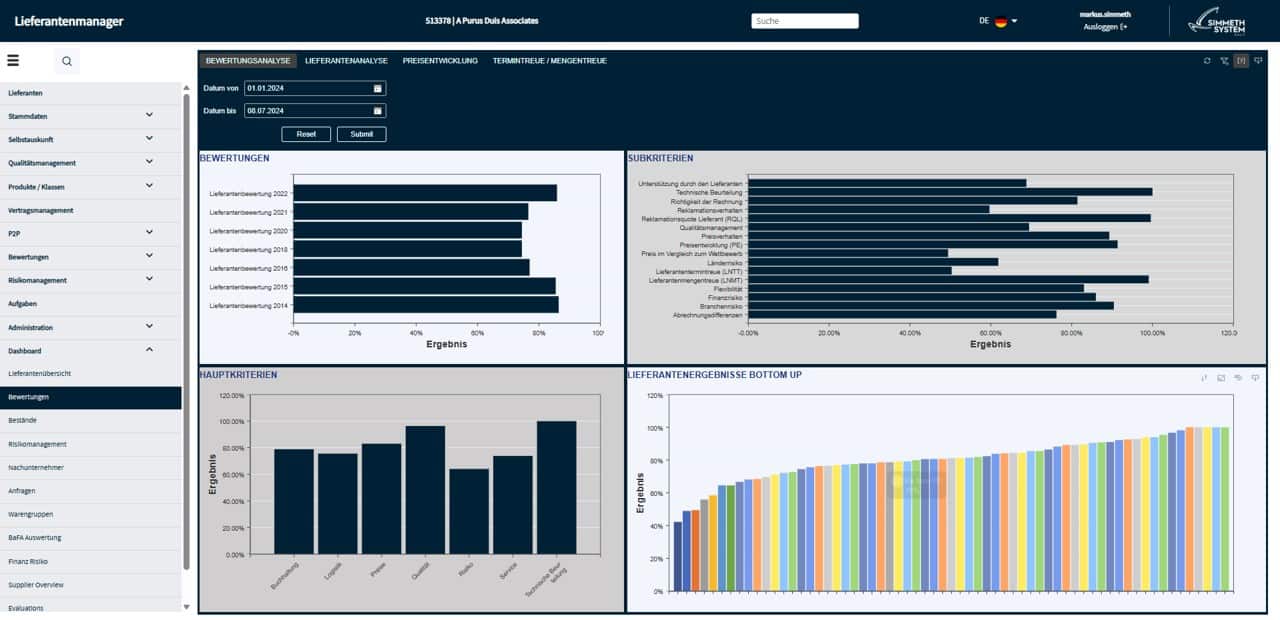

The digitalization of supplier audits offers companies considerable advantages in terms of efficiency, traceability and scalability. Instead of relying on manual processes and paper-based documentation, digital solutions such as Simmeth’s SCM software SC-Manager enable automated and structured execution of all audit phases – from planning and execution through to action tracking.

7.1. Supplier audit software – digitalization & automation

Modern supplier audit software digitally maps the entire audit process, creating a central platform for auditors and those responsible. The automation of recurring tasks such as scheduling, notifications, assessment recording and report generation reduces the workload and significantly increases data quality.

Important functions of digital audit solutions:

- Digital questionnaires and checklists with flexible customization depending on supplier type

- Real-time documentation during the audit via tablet, smartphone or laptop

- Central database for archiving audit reports, action plans and supplier profiles

- Automatic evaluations and KPIs for comparability between suppliers

- Workflow-controlled action tracking including deadlines and escalation mechanisms

- Integration into existing ERP, QM, SCM software and the supplier management software

This not only speeds up the audit process, but also makes it much more transparent and traceable – a major advantage in terms of compliance and continuous supplier development.

8.2. Audit report supplier audit template – Structured documentation

Another component of digital auditing is the structured documentation of the results using standardized audit report templates. These templates contain all the relevant fields for:

- Supplier data and audit description

- Audit objectives and scope

- Evaluation of the individual criteria (e.g. traffic light system or scoring)

- Deviations or risks identified

- Agreed measures including responsibilities and deadlines

- Overall result of the audit and recommendations for action

The standardized structure ensures that all audits are comparable and that important findings can be recorded and processed quickly. At the same time, digital documentation facilitates subsequent evaluation, archiving and tracking – which in turn contributes to the ongoing optimization of the supply chain. In short, the digitalization of supplier audits is a decisive step towards greater quality, transparency and efficiency in supplier management.

Would you like to find out more about our digital solution for supplier audits?