Targeted supplier development is the key to stable, resilient supply chains – and therefore to ensuring long-term quality, security of supply and competitiveness in times of global challenges.

1. what is supplier development

1.1. Definition of supplier development

Supplier development describes all strategic and operational measures with which a company specifically improves the performance of its suppliers. The aim is not only to increase the quality of the products and services supplied, but also to sustainably strengthen the efficiency and stability of the entire supply chain. This approach is becoming increasingly important, particularly in the face of globalized competition, as close cooperation with efficient partners is becoming a decisive factor for success.

1.2. Basics of supplier development

At its core, supplier development aims to systematically identify weaknesses in supplier performance and eliminate them through targeted development measures. This is not just about short-term improvements, but about sustainably increasing performance, for example through technical support, training or joint process optimization. Strategic purchasing plays a central role here, as it actively shapes and manages both the selection of suitable suppliers and the development partnerships.

1.3. The benefits for companies

Consistent supplier development offers numerous advantages for companies: it lowers procurement costs in the long term, increases product quality and reduces risks along the supply chain. At the same time, it leads to stronger ties with key partners, which proves to be a stabilizing factor, especially in times of crisis. In addition, it enables competitive advantages by identifying innovation potential at an early stage and realizing it together with suppliers.

2. types of supplier development

Supplier development can basically be divided into two main forms: active and passive measures. Both pursue the goal of increasing supplier performance, but differ in terms of methodology, intensity and strategic objectives. While active development focuses on long-term partnerships and cooperation, passive development is based more on control and clear communication of expectations. The choice of a suitable strategy depends largely on the status and strategic relevance of the supplier in question.

2.1. Active supplier development

Active supplier development is characterized by intensive cooperation between the purchasing company and the supplier. The focus is on joint training, regular coordination and the cooperative resolution of problems. The aim is not only to improve suppliers, but to develop them into long-term strategic partners with whom innovations and process improvements go hand in hand.

2.2. Passive supplier development

In contrast, passive supplier development focuses on the clear communication of expectations and the monitoring of performance against defined standards. Audits, quality checks or key performance indicators are used to ensure compliance with these requirements. This method requires fewer resources and can be implemented more quickly, but offers only limited opportunities to influence far-reaching improvements.

2.3. Exemplary applications

Both forms of supplier development are widely used in practice – often even in combination. While technology-intensive sectors such as the automotive industry primarily rely on active development, companies with standardized products tend to use passive methods. The modular use of both approaches makes it possible to react flexibly to different types of suppliers and market requirements.

3. supplier development process

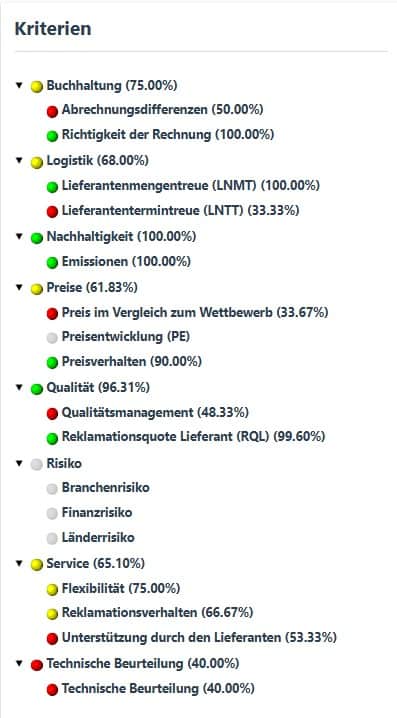

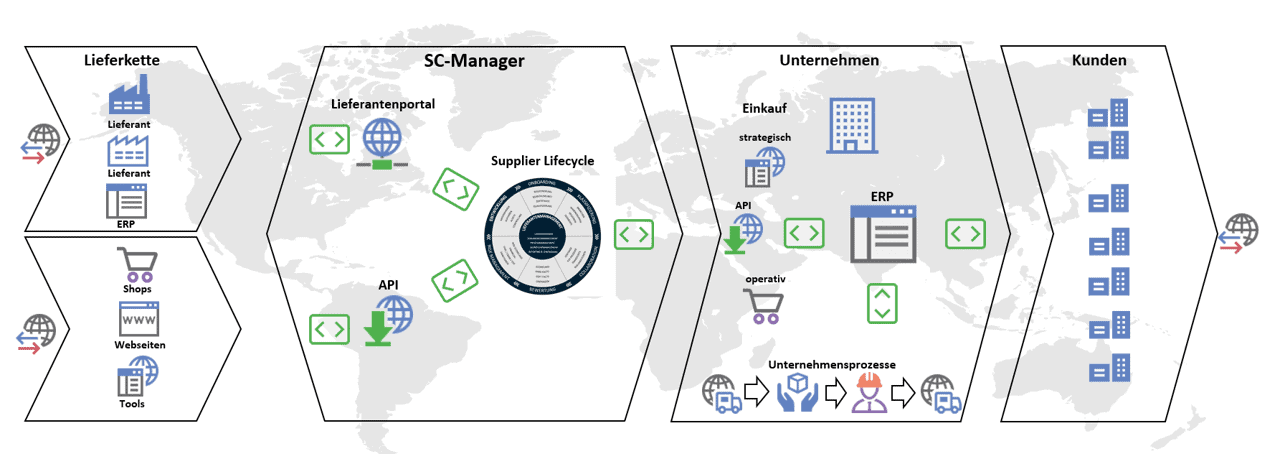

Successful supplier development follows a structured, clearly defined process. This begins with a well-founded analysis of supplier performance through a supplier evaluation, leads to targeted measures for improvement and often ends in a long-term partnership. It is essential to use methodical tools such as supplier evaluation software, if possible embedded in SRM software such as Simmeth’s SC-Manager, as well as established standards such as IATF 16949, and to dovetail them closely with quality management.

3.1. Relevant standards for supplier development

ISO 9001 – Quality management systems

Focus: General quality standard with requirements for supplier assessment, continuous improvement and documentation.

Relevance: Basic requirement for quality-oriented supplier development in almost all industries

IATF 16949 – Quality management in the automotive industry

Focus: Specification based on ISO 9001 with additional requirements specifically for automotive suppliers.

Relevance: Mandatory standard for OEM-related suppliers, in particular for development responsibility and series production.

ISO 14001 – Environmental management systems

Focus: Requirements for suppliers in terms of environmental responsibility, resource efficiency and sustainability.

Relevance: Important in the selection and development of suppliers in the context of sustainable supply chains.

ISO 45001 – Occupational health and safety management systems

Focus: Health and safety in the supply chain.

Relevance: Relevant for supplier development programs with a focus on social responsibility

ISO 26000 – Guidance on social responsibility

Focus: Corporate Social Responsibility (CSR) in the entire supply chain.

Relevance: Guidance for ethically sustainable supplier development and supplier audits

SA8000 – Social standard for working conditions

Focus: Human rights, working time regulations, occupational health and safety and fair pay.

Relevance: Particularly relevant for international supplier relationships.

VDA 6.3 – Process audit standard in the automotive industry

Focus: Evaluation and development of processes along the supply chain.

Relevance: Industry standard for operational assessment and targeted further development

ISO/IEC 27001 – Information security management

Focus: Protection of company data and IT systems within the supply chain.

Relevance: Increasingly important in the selection and development of digitally networked or IT-sensitive suppliers

These standards offer companies a structured and standard-compliant basis for aligning their supplier development with both regulatory requirements and internal quality and sustainability goals. When integrated into modern SRM systems such as Simmeth’s SC-Manager, these requirements can be implemented and monitored particularly efficiently.

3.3. Development process

The first step in any supplier development process is a comprehensive analysis and evaluation of suppliers based on relevant key figures. Subsequently, targets are jointly agreed and action plans are defined that are tailored to the supplier’s individual strengths and weaknesses. Regular feedback loops and continuous performance reviews ensure that the measures take effect and have a lasting impact.

3.4. Overview: Tools and methods of supplier development

Numerous tools are available for implementation: The supplier development portfolio helps with strategic classification, while maturity models and scorecards create transparency and make progress measurable. This is supplemented by audits and benchmarking as supplier development methods that provide valuable insights into strengths and potential for improvement.

| Tool / Method | Purpose | Benefit |

|---|---|---|

| 1. supplier development portfolio | Strategic classification of suppliers | Targeted selection and prioritization |

| 2. maturity models | Assessment of the stage of development | Identification of specific development needs |

| 3. scorecards | Measurement and comparison of key performance indicators | Transparent presentation of performance |

| 4. audits | Systematic review of processes and quality | Recognizing weaknesses at an early stage |

| 5. benchmarking | Comparison with competitors and best practices | Derivation of potential for improvement |

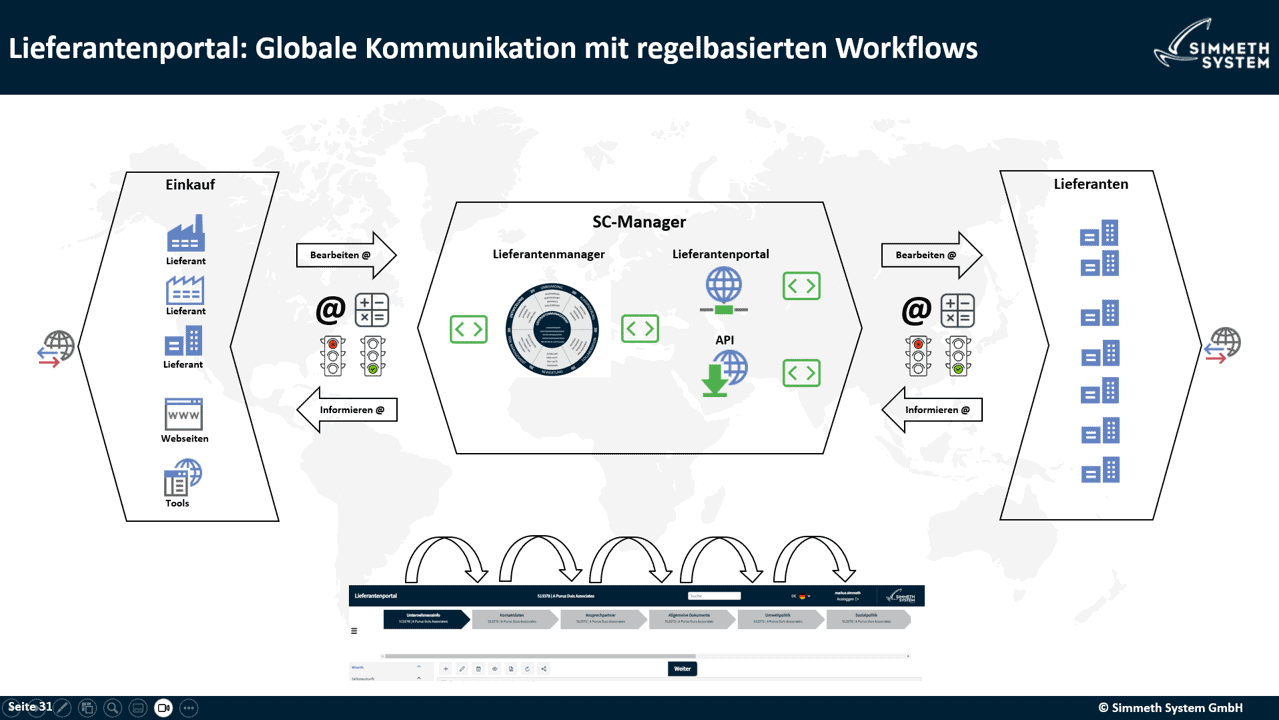

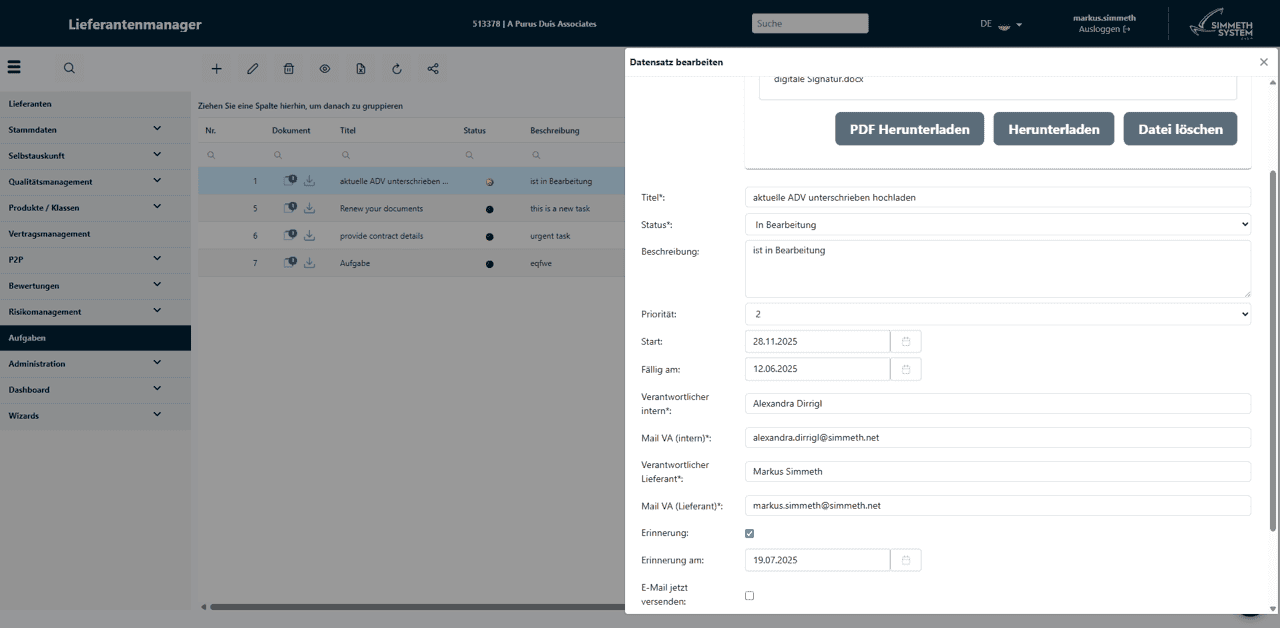

3.5. Supplier development in supplier management

Effective supplier development is firmly anchored in supplier management . It forms the interface to quality and risk management and is strategically managed by Purchasing. KPIs and supplier evaluations can be used to monitor developments on an ongoing basis and expand them in a targeted manner.

Suppliers are directly integrated into the process via a supplier portal – from digital self-disclosure and the transparent communication of assessment results to the structured transmission and processing of tasks in action management. This not only encourages suppliers to take responsibility, but also increases the efficiency and traceability of work processes and all development activities.

4. tasks of supplier development

Supplier development fulfills a variety of tasks that go far beyond simply improving quality. It recognizes potential, implements targeted improvement measures and makes a decisive contribution to the development of long-term, stable partnerships.

Supplier development fulfills a variety of tasks that not only aim to improve quality, but also have a strategic impact. On the one hand, potential is identified at an early stage and, on the other, targeted improvement measures are implemented, which at the same time significantly promotes the development of long-term, stable partnerships. In detail, the central tasks can be summarized as follows:

4.1. Typical tasks of supplier development

- Supplier selection and classification

Selection of suitable suppliers based on strategic criteria and classification according to relevance and performance. - Potential analysis and risk assessment

Identification of strengths, weaknesses and possible risks and opportunities in the collaboration. - Target definition and action planning

Joint agreement on development targets and creation of specific action plans to improve performance. - Implementation of development measures

Implementation of planned measures such as training, process optimization or technical support. - Monitoring and performance evaluation

Ongoing monitoring of development progress using KPIs, scorecards and regular feedback meetings. - Coordination with specialist departments

Coordination with production, quality assurance, logistics and other relevant units for holistic development. - Communication with suppliers

Continuous exchange, transparent communication and building a trusting, cooperative relationship. - Integration into supplier management

Anchoring development in strategic supplier management as well as in quality and risk management. - Standardization and documentation

Definition of uniform procedures and documentation of the results for traceability and certifiability.

4.2. Role of purchasing in the process

Purchasing assumes a coordinating role within supplier development. It mediates between specialist departments and suppliers, controls the development steps and ensures that all measures are sustainably integrated into the supply chain.

4.3. Prerequisites for effective implementation

Successful implementation of supplier development requires clear internal coordination between purchasing, quality assurance and other relevant departments. Equally important is methodical support, for example through structured workshops, training courses or templates for defining objectives. Continuous communication with suppliers is also crucial in order to communicate measures transparently and promote trusting cooperation.

Uniform standards and clearly defined procedures ensure that the process is binding and create a reliable basis for evaluating and managing supplier performance. The professional implementation of the supplier management software by Simmeth offers methodical support right from the introductory phase – for example through ready-made process models, industry-proven workflows and customizable templates and scorecards, for example for supplier evaluation. In live operation, the system then provides the necessary tools for documenting goals, tracking progress and systematically evaluating KPIs. This not only facilitates implementation, but also ensures the sustainable effectiveness of supplier development.

4.4. Elements of a development concept

An effective supplier development concept first defines clear objectives and roles. Based on suitable KPIs and evaluation criteria, the measures can be implemented in a structured manner and adjusted through regular reviews if necessary.

4.5. The benefits of a clear concept

A well thought-out concept enables transparent communication with suppliers, supports systematic action planning and ensures a sustainable increase in efficiency in procurement in the long term.

Example: Concept for the development of A-suppliers in mechanical engineering:

A medium-sized mechanical engineering company identifies its five most important A-suppliers for precision parts as strategically critical. A multi-stage supplier development program is set up on the basis of a clearly structured concept:

- Initial evaluation: All five suppliers are evaluated using scorecards for quality indicators, delivery reliability and innovation capability.

- Target agreements: Individual development targets are defined for each supplier (e.g. reducing the complaint rate by 25% in 12 months).

- Action planning: Planned measures include joint process analyses, workshops on lean principles and technology transfer.

- Accompanying monitoring: Monthly KPI evaluations and quarterly review meetings ensure transparency and follow-up.

- Result: After one year, the company has seen a significant reduction in reworking costs and a more stable delivery performance.

Conclusion: The structured concept not only led to measurable improvements, but also to a stronger partnership – a clear competitive advantage for future projects.

4.6. Integration into the company system

Supplier development should always be in line with the overarching purchasing strategy, while at the same time close integration with quality management is required in order to make effective use of synergies. In addition, modern SCM software solutions – such as the SC Manager from Simmeth – support the digital implementation, structured control and continuous monitoring of all development measures.

5. strategic supplier development

Strategic supplier development aims to build long-term partnerships while systematically minimizing risks in the procurement process. It makes targeted use of proven development methods in order to strengthen key suppliers on the one hand and to sustainably promote innovation on the other.

5.1. Strategic goals and planning

Long-term competitive advantages arise when supplier development becomes an integral part of the corporate strategy. A particular focus is placed on key suppliers with whom sustainable synergies and joint future projects can be implemented.

5.2. Measures for supplier development and implementation

Strategic measures include, for example, training programs, co-engineering projects and targeted technology transfer. This close cooperation enables companies to develop new market opportunities and drive innovation together with their suppliers.

Strategic measures for supplier development – overview

- Training programs

Goal: to build up know-how and quality awareness among supplier personnel. - Co-engineering projects

Goal: Joint product development and optimization of technical solutions. - Technology transfer

Objective: Passing on technological standards and processes to increase efficiency. - Supplier innovation workshops

Objective: To promote creativity and innovative strength through the structured exchange of ideas. - Long-term framework agreements

Goal: planning security and reliability in cooperation. - Joint investments

Goal: Sharing risks and expanding strategic ties. - Integration into development processes

Goal: Early involvement of suppliers in new product and process developments. - Partnership target agreements

Objective: Strengthening the commitment and strategic focus of cooperation.

5.3. Industry examples in comparison

Industries such as aerospace, automotive and mechanical engineering have different approaches to supplier development. While the aviation industry focuses on the highest safety requirements, automotive manufacturers are increasingly focusing on standardization and efficiency. Mechanical engineering, on the other hand, scores with flexible, medium-sized partnerships.

6. challenges in practice

The implementation of supplier development poses various challenges in practice. These include, among others

- Different degrees of maturity of the suppliers

- internal time and resource expenditure and

- lack of acceptance on the part of suppliers.

This makes it all the more important to adopt a structured approach that involves all stakeholders at an early stage.

7. best practices and tools

Numerous best practices and tried-and-tested tools support the successful implementation of supplier development. They provide orientation, help with structuring and enable systematic monitoring of success.

7.1. Successful examples

Practical examples from various industries show how companies have been able to achieve measurable improvements with their suppliers by using the SC Manager from Simmeth – for example at Messe München or VBZ Verkehrsbetriebe Zürich.

7.2. Useful tools and checklists

Helpful tools such as Simmeth’s SC Manager as a digital toolkit for purchasing with integrated supplier evaluation and action management simplify day-to-day work and increase transparency.

If it is not possible to use a professional solution, standardized checklists also offer several advantages: Firstly, they create a uniform evaluation framework that applies equally to all suppliers. This reduces subjective assessments and increases comparability. Secondly, standardization helps to increase efficiency, as recurring inspection processes are clearly structured and time-saving.

7.3. What you should avoid

The most common errors include

- Unilateral measures without feedback

- Too little involvement of suppliers

- Lack of measurability of the results

- No use of professional tools or at least checklists

Only those who avoid these pitfalls can achieve lasting effects.

Only those who avoid these pitfalls can achieve lasting effects.

8 Conclusion: Supplier development is a strategic lever and operational tool

Suppliers are actively and systematically integrated into the process via a supplier portal, starting with the digital self-disclosure, through the transparent communication of assessment results, to the structured transmission and processing of tasks in action management. It is crucial to select the appropriate methods, define clear objectives and systematically integrate development into the company’s processes. Whether actively or passively, whether in accordance with IATF specifications or through our own standards: professional supplier development pays off in the long term – economically, operationally and strategically.

Would you like to find out more about our digital solution for supplier development?