1 What is Supply Chain Management – SCM Software?

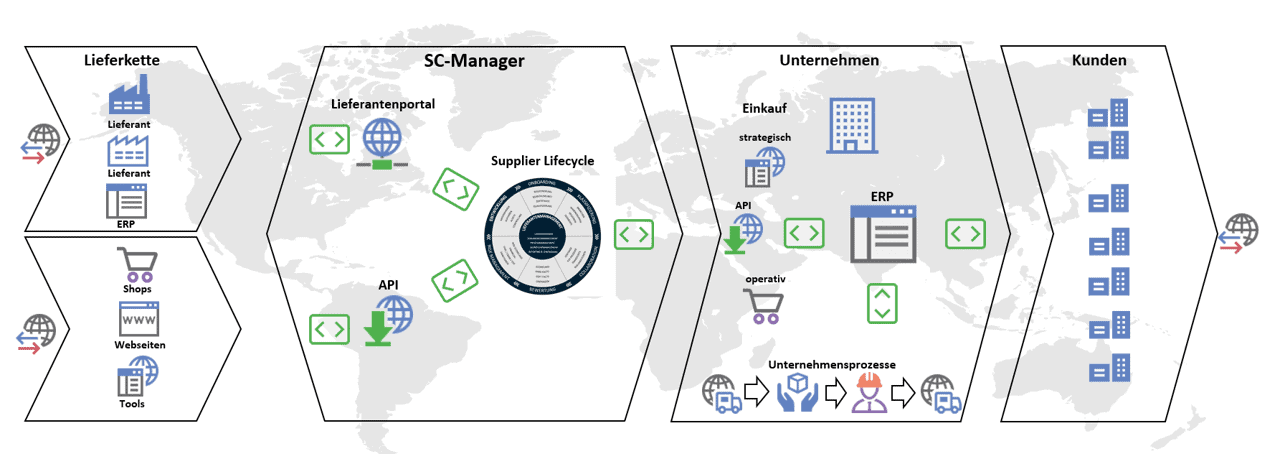

The modern, globalized economy requires efficient and transparent supply chains. supply chainsto meet the increasing demands for speed, accuracy and cost efficiency. SCM software plays a central role here by helping companies to optimize their entire supply chain processes, avoid bottlenecks and use resources more efficiently.

1.1. Definition and mode of operation

Supply chain management software systems are specialized IT tools that help companies to better plan, control and monitor their supply chains. These SCM tools usually collect, analyze and process data in real time in order to improve decision-making processes and identify bottlenecks in production or logistics at an early stage. SCM software integrates various modules for inventory management, demand planning, production control, transportation and procurement so that all relevant business areas work together efficiently.

1.2. Difference between ERP systems and specialized SCM solutions

A common misconception is that ERP (Enterprise Resource Planning) systems cover the same functions as SCM IT. While ERP systems integrate a large number of business processes in a company, supply chain management systems are specifically tailored to the optimization of supply chain processes. ERP systems often provide basic functions for inventory management and logistics, while specialized SCM systems offer deeper analysis, real-time monitoring and more precise planning capabilities. Companies with complex or global supply chains therefore benefit in particular from specialized SCM software.

1.3. Areas of application in companies

SCM software is used in almost all industries that rely on efficient supply chains. This includes retail, production, e-commerce e-commerce and logistics. Retailers use supply chain software, for example, to better manage stock levels and optimize ordering processes. Manufacturing companies use it to synchronize production processes and avoid material bottlenecks. In e-commerce, the software enables seamless integration of delivery services, while logistics companies use real-time tracking and optimized route planning to reduce transport times.

1.4. Differentiation from logistics

Although supply chain management and logistics are closely linked, there are significant differences. While logistics focuses on the physical transportation, storage and distribution of goods, SCM encompasses strategic and comprehensive management of the entire supply chain. SCM software not only looks at transport, but also optimizes strategic purchasing, supplier management, procurement, production and customer service by integrating and analyzing all the processes involved.

2. important functions of innovative SCM software

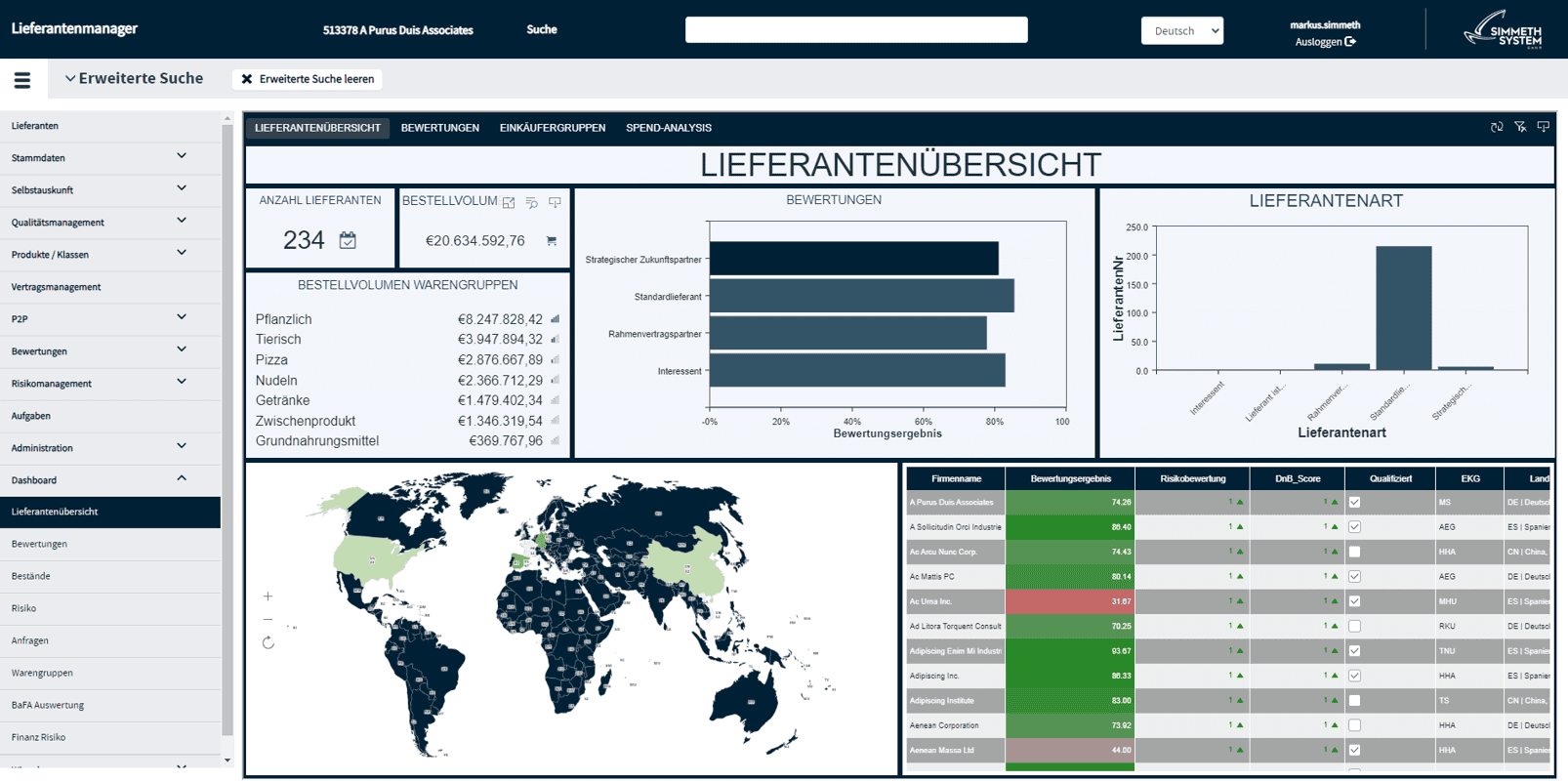

2.1. Strategic purchasing and supplier management

An optimized supplier management is one of the core functions of SCM software. Companies benefit from a strategic selection of their suppliers, which can reduce costs and ensure the quality of the goods and services supplied

Modern SCM solutions offer functions for evaluating and monitoring suppliers on the basis of performance criteria such as punctuality, quality and cost structure. This enables companies to build long-term, stable relationships with their most important suppliers and minimize risks within the supply chain.

In addition, companies can benefit from automated tendering and contract management processes that optimize the entire purchasing process. Intelligent demand forecasting and strategic purchasing planning help to better manage purchasing volumes and benefit from better conditions.

2.2. Risk management, sustainability and compliance

SCM software plays a crucial role in risk management by recognizing potential disruptions within the supply chain at an early stage and providing alternative scenarios. This includes, for example, the identification of geopolitical risks, production downtimes or delivery delays due to natural disasters. By using real-time data, companies can react more quickly to unexpected events and make their supply chains more resilient.

Another important aspect is sustainability. Companies are under increasing pressure to implement environmentally friendly and socially responsible supply chains. SCM software helps to record CO₂ emissions, identify more environmentally friendly transportation routes and integrate sustainability criteria into the purchasing process.

SCM software also supports companies in adherence to legal regulations and compliance guidelines, especially in international trade. Automated documentation and reporting functions facilitate compliance with regulatory requirements, for example in the area of customs regulations or product certifications. Companies can therefore not only minimize legal risks, but also improve their brand image through a transparent and sustainable supply chain.

2.3. Procurement and delivery

Another essential module of SCM software relates to procurement and supply logistics. Modern SCM solutions automate ordering processes, optimize purchasing and support close collaboration with suppliers. By digitizing procurement processes, i.e. e-procurement , companies can improve their supplier relationships, reduce purchasing costs and identify bottlenecks at an early stage.

One particular advantage is the ability to monitor the status of deliveries at any time using real-time tracking functions. This enables companies to react quickly to delays or unexpected problems and develop alternative logistics strategies. This is a decisive competitive advantage, especially in global supply chains, as it helps to minimize delays and make the entire supply chain more resilient.

2.4. Planning and production

One of the central functions of a modern supply chain management system is the strategic planning and control of production processes. Efficient SCM software records and processes relevant supply chain data in real time, enabling companies to carry out more precise demand planning. This not only contributes to better inventory control, but also reduces the risk of supply bottlenecks and overproduction.

By automating and optimizing production processes, companies can reduce their warehousing costs without compromising product availability. Powerful SCM software also enables seamless communication between different departments and production sites. As a result, inefficient processes can be avoided and production capacities can be optimally utilized. Companies are given the opportunity to make production processes more flexible and thus react more quickly to short-term fluctuations in demand.

2.5. Returns management and logistics

Efficient returns management is particularly important for e-commerce companies. SCM software offers automated processes for handling returns, which reduces the administrative workload and speeds up the entire returns process. This not only increases operational efficiency, but also customer satisfaction, as customers receive their refunds or replacement deliveries more quickly.

SCM software also optimizes logistics processes by reducing transport costs in the supply chain and shortening delivery times. Intelligent algorithms and data analysis can be used to optimize routes for transporting goods, enabling companies to use their resources more efficiently and pursue a more environmentally friendly logistics strategy.

3. advantages of SCM software

3.1. Efficiency and cost savings

By automating and optimizing supply chain processes, SCM software significantly increases operational efficiency. With the help of suitable software solutions, companies can manage their inventories in a more targeted manner, avoid overproduction and reduce transportation costs. These measures not only lead to direct cost savings, but also improve overall competitiveness. By using resources more efficiently, companies can make optimum use of their production capacities and increase their profit margins.

Another advantage is the reduction of rejects and production errors. More accurate demand forecasting and automated control of replenishment processes help to avoid bottlenecks, allowing both material and personnel costs to be used more efficiently. The reduction of manual processes also minimizes sources of error and improves quality assurance. Companies that use modern SCM software benefit in the long term from a sustainable optimization of their operational processes.

3.2. Transparency and accuracy

One of the biggest challenges in supply chain management SCM is the lack of transparency regarding inventories, orders and delivery times. SCM software offers comprehensive functions for inventory and order management, giving companies a complete overview of their supply chain at all times.

Real-time data analysis enables bottlenecks to be identified at an early stage and proactively resolved. This not only leads to better planning, but also improves the quality and reliability of the entire supply chain. With the help of AI-supported forecasting models, companies can estimate demand trends more precisely and dynamically adjust their stock levels to avoid both surpluses and shortages.

In addition, high to real-time transparency allows for better traceability of goods movements. Companies can use software solutions with real-time tracking systems to monitor the status of their deliveries and inventories at all times. This allows deviations from the planned process to be quickly identified and appropriate countermeasures to be taken. Automatic e-mail alerts can play an important supporting role here.

3.3. Cooperation and communication

Another key benefit of SCM software is the improved collaboration between companies, suppliers and customers. The software facilitates supplier management and the procurement process by enabling transparent communication and improved coordination between all parties involved.

Thanks to shared digital platforms, suppliers and logistics partners have access to relevant data in real time, which improves the ability to react in crisis situations. This allows delays or disruptions in the supply chain to be identified quickly and countermeasures to be initiated at an early stage. Companies that ensure seamless communication with their partners can thus guarantee a more stable and reliable flow of goods.

Many modern SCM tools also offer industry-specific adaptations so that companies can easily implement their individual requirements. Functions such as automated order confirmations, shipping notifications or seamless integration into ERP systems ensure smooth collaboration with external partners.

4. selection of the right SCM provider

The choice of suitable SCM software depends on several factors. Companies should ensure that the chosen solution can be seamlessly integrated into existing IT systems and is future-proof . Scalability plays a key role here, as companies grow and need to flexibly expand their SCM solution.

User-friendliness and support are also decisive criteria. An intuitive user interface and ease of use can make implementation much easier. The question of whether a cloud-based or on-premise solution is the better choice should be clarified on an individual basis. While cloud solutions are generally more cost-effective and flexible, on-premise variants offer more control over data and security.

5. implementation of SCM software

The introduction of SCM software requires careful planning. Companies should first define their specific requirements and evaluate suitable software solutions. Once the right system has been selected, data migration follows, during which existing data must be correctly transferred to the new system.

A comprehensive test phase is essential in order to identify and rectify errors at an early stage. Employees should also be trained so that they can use the software efficiently. Competent support from the provider facilitates implementation and ensures smooth operation.

In addition, a gradual rollout of the software is recommended in order to make any necessary adjustments and avoid disrupting ongoing operations. Companies should work closely with the software provider to develop a customized solution that is optimally tailored to their business processes.

6. costs of SCM tools

The cost of SCM software varies depending on the range of functions and company size. Many providers offer flexible pricing models that are based on the individual needs of the company. There is also often the option of using a free trial version to evaluate the software in advance.

However, in addition to license costs, companies should also consider costs for implementation, training and ongoing maintenance. Cloud-based solutions are often associated with monthly subscription costs, while on-premise solutions can result in higher initial investments but lower operating costs in the long term.

7 Conclusion & outlook

SCM software will play an even more important role in the future. The increasing digitalization and automation of supply chain processes enable more efficient, transparent and flexible management of the entire supply chain, i.e. the value chain. Companies that invest in modern SCM solutions at an early stage will benefit from significant efficiency gains, cost savings and better adaptability to market fluctuations.

A decisive factor for future development is the integration of new technologies such as artificial intelligence (AI) and machine learning. These enable more precise demand forecasting, optimized warehousing and forward-looking planning of production and logistics processes. AI-supported algorithms can analyze bottlenecks in real time, suggest alternative delivery routes and use predictive analytics to detect failures or delays at an early stage.

In addition, the Internet of Things (IoT) will further improve transparency within the supply chain for supply chain management SCM. By using sensors and real-time data analysis, companies can monitor the status of their goods and raw materials at all times. This not only makes it easier to control production processes, but also enables better product traceability. This can represent a decisive competitive advantage, particularly in sensitive sectors such as the food industry or healthcare.

Another forward-looking topic is blockchain technology. This enables tamper-proof, decentralized storage of transaction and supply chain data. This enables companies to fully document the origin and quality of goods, which is particularly important in international trade and for sustainable supply chains.

In addition to technological developments, sustainability will also play an increasingly important role in supply chain management. Companies need to reduce their CO₂ emissions, use more environmentally friendly transportation routes and implement sustainable procurement strategies. Modern SCM software supports these processes by facilitating environmentally friendly route planning, optimized warehouse strategies and the selection of sustainable suppliers.

In conclusion, it can be said that companies that rely on digital and innovative SCM solutions at an early stage are better positioned in the long term. Not only can they reduce their costs and optimize their processes, but they can also react more flexibly to market changes. The future of supply chain management will be characterized by data-driven decisions, automation and globally networked supply chains. Those who actively shape these developments will strengthen their competitiveness in the long term and be ideally equipped for future challenges.